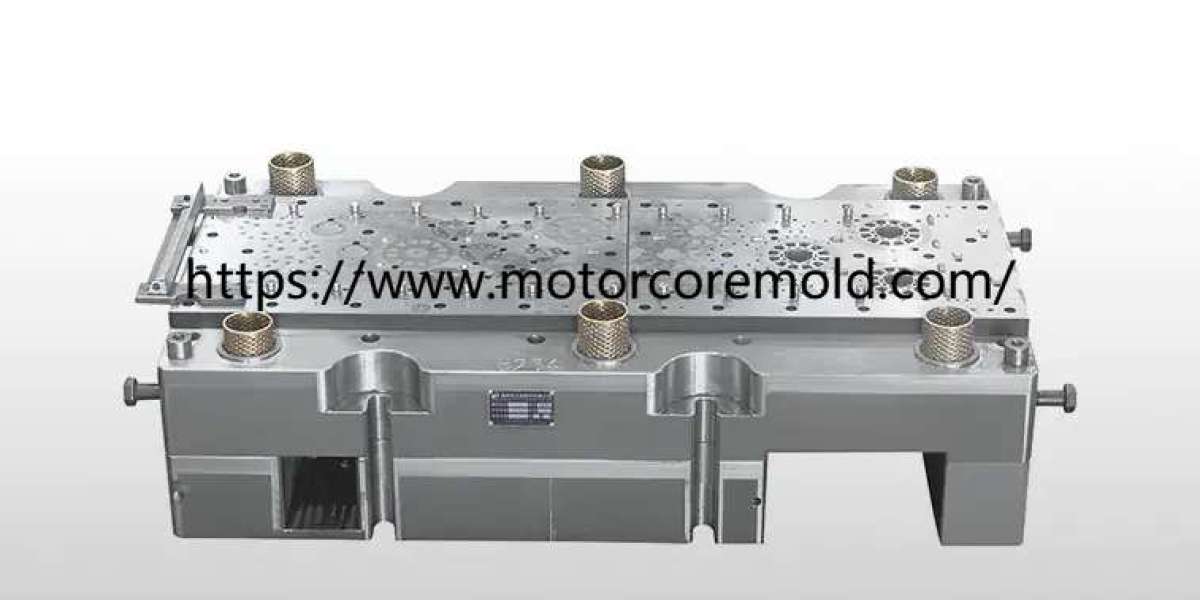

In the manufacturing world, the performance and longevity of a High Speed Progressive Stamping Die are largely determined by the choice of materials and the application of advanced surface treatments. As production demands rise and tolerance requirements become tighter, selecting the right mold steel and employing effective surface enhancements are critical to ensure consistent quality and operational efficiency. Understanding how these factors influence the durability and wear resistance of a High Speed Progressive Stamping Die can provide manufacturers with the competitive edge necessary for sustained success.

Selecting the Optimal Mold Steel for High Speed Progressive Stamping Die

The core of any reliable High Speed Progressive Stamping Die lies in the steel used for its construction. Mold steels must combine hardness, toughness, and fatigue resistance to withstand the intense and rapid mechanical stresses characteristic of high-speed stamping operations. Commonly used materials include D2. A2. and S7 tool steels, each offering a balance of wear resistance and impact strength.

D2 steel, known for its high carbon and chromium content, provides excellent hardness and abrasion resistance, making it a popular choice for cutting and blanking components of a Speed Progressive Stamping Die. However, it is somewhat less tough compared to other steels, so it is often paired with strategic design to minimize shock impact.

A2 tool steel presents a good compromise between hardness and toughness, making it suitable for parts of the High Speed Progressive Stamping Die exposed to varied stresses. Its air-hardening property allows for easier heat treatment, optimizing performance without compromising structural integrity.

S7 steel is favored where impact resistance is paramount. For components in a High Speed Progressive Stamping Die that endure sudden loads or shocks, S7 reduces the risk of cracking or premature failure, albeit with slightly lower wear resistance than D2.

| Comprehensive life: | ≥160 million punches |

| Blade die life: | ≥5 million strokes/0.1mm |

| Mold structure: | Three-plate mold base + ball guide |

| Effective cutting edge height: | ≥8mm |

| Blade material: | DJ40 |

| Grooved die form: | Punch grooved die, slow wire finishing, the punch is polished using a special process to remove the oxidation layer |

| Guide parts: | Precision + high hardness |

| Blanking speed during running-in period: | 80-280 punches/minute |

| Blanking speed: | 280-300 punches/minute |

| Concentricity: | ≦0.05mm |

| Protection device: | Equipped with misfeed protection device |

| Punching burr: | ≦0.05mm |

| Riveting force: | 30N |

| Safety device: | Misfeed detection + equal height limit column |

| Product output form: | Conveyor belt Rotor control device Chute control device |

| Plate control device: | Cylinder |

| Mold base material: | Upper and lower mold seats P20. middle unloading seat P20. the second and fourth levels are made on the same set of molds and are interchangeable during production. The shaft hole can be used for three interchangeable pumping plates. |

| Spare parts provided: | 30% of wearing parts |

| Internal plate material: | Cr12MOV |