Multi-Tasking Machine Tools Market Overview:

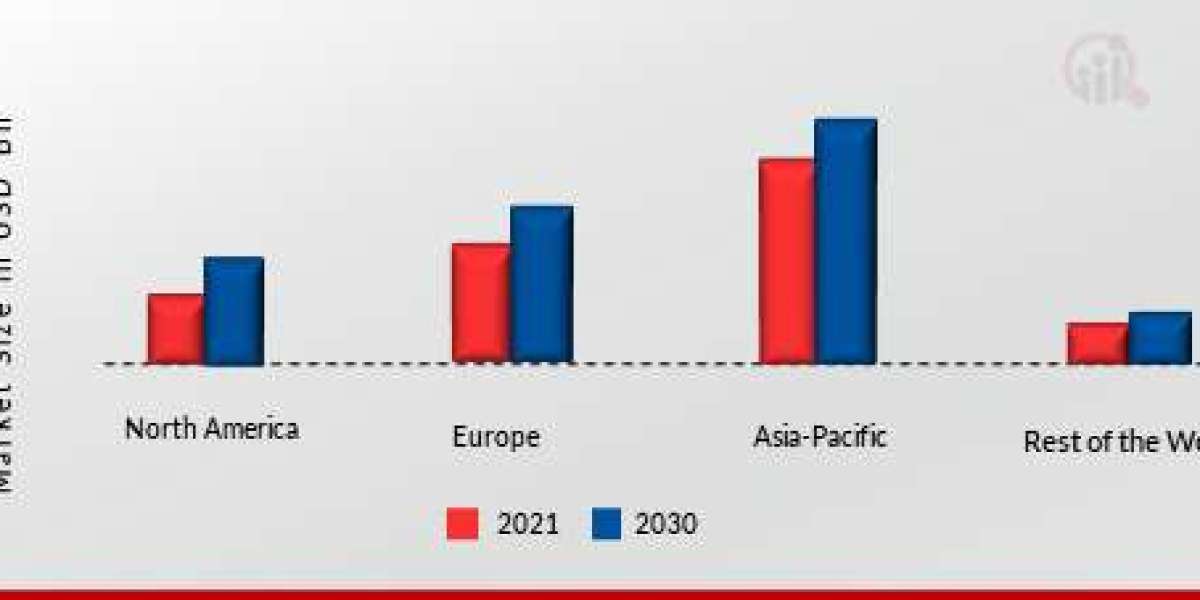

In 2021, the global market for multitasking machine tools was estimated to be worth USD 1084.99 billion. According to projections, the market for multi-tasking machine tools will increase from USD 1117.33 billion in 2022 to USD 1413.2 billion by 2030.

Multi-Tasking Machine Tools represent a significant leap forward in machining technology, enabling manufacturers to perform multiple operations on a single machine. These tools integrate various machining capabilities such as milling, turning, drilling, and grinding, streamlining the production process and enhancing overall efficiency. The market for multi-tasking machine tools is witnessing remarkable growth as industries seek to optimize their manufacturing operations, reduce lead times, and improve product quality.

For latest news and updates, request a free sample report on Multi-Tasking Machine Tools Market

By Segmentation:

1. Type of Multi-Tasking Machine:

The market is segmented based on the type of multi-tasking machine tools, including mill-turn centres, turn-mill centres, and multi-axis machining centres. Each type offers specific advantages in terms of complexity, precision, and the range of operations it can perform.

2. End-User Industries:

Segmentation by end-user industries distinguishes between sectors leveraging multi-tasking machine tools. Industries such as aerospace, automotive, medical, and energy have unique requirements, influencing the design and capabilities of multi-tasking machines for optimal performance in specific applications.

3. Applications:

The market is further segmented by applications, emphasizing the diverse functions these machines can perform. From complex parts in aerospace components to high-precision medical devices, multi-tasking machine tools are versatile solutions that cater to a broad spectrum of manufacturing needs.

Key Takeaways:

1. Enhanced Operational Efficiency:

A primary takeaway from the Multi-Tasking Machine Tools Market is the significant enhancement in operational efficiency. By consolidating multiple machining processes into a single machine, manufacturers can reduce setup times, minimize workpiece handling, and improve overall workflow, leading to increased productivity.

2. Versatility in Machining Operations:

The market reflects a growing demand for versatile machining solutions. Multi-tasking machine tools enable manufacturers to perform various operations on a single platform, eliminating the need for separate machines and ensuring seamless transitions between different machining processes.

3. Precision and Quality Improvement:

Multi-tasking machine tools contribute to precision and quality improvement in manufacturing. The integration of advanced technologies, such as CNC (Computer Numerical Control) systems and real-time monitoring, allows for tight tolerances and consistent quality across diverse applications.

Regional Insights:

1. Asia-Pacific:

The Asia-Pacific region dominates the Multi-Tasking Machine Tools Market, driven by the thriving manufacturing sectors in countries like China, Japan, and South Korea. The region's robust automotive, aerospace, and electronics industries contribute significantly to the demand for advanced multi-tasking machines.

2. North America:

North America boasts a mature market with a strong focus on technological innovation. The aerospace and medical device industries in the United States, in particular, drive the demand for high-precision multi-tasking machine tools. Additionally, the region's emphasis on automation and efficiency fuels market growth.

3. Europe:

Europe places a significant emphasis on precision engineering and high-quality manufacturing. The aerospace and automotive industries in countries like Germany and the United Kingdom contribute to the demand for advanced multi-tasking machines. The region's commitment to technological advancements positions it as a key player in the market.

The Multi-Tasking Machine Tools Market is a pivotal force in the evolution of modern manufacturing, offering industries the ability to streamline operations and achieve unprecedented levels of precision and efficiency. As manufacturing demands continue to evolve, the market responds with innovative solutions that cater to diverse applications.

Top trending report: