In the world of industrial valves, the knife gate valve is a unique and essential player. This valve has earned its name from its sharp-edged gate designed to slice through thick and challenging media, making it an ideal choice for a variety of applications. In this comprehensive blog post, we’ll dive into the functions, types, and applications of the knife gate valve, shedding light on its pivotal role in industries around the globe.

Understanding the Knife Gate Valve

Before we explore the various facets of knife gate valves, let’s start with a basic understanding of what they are and how they work.

What is a Knife Gate Valve?

A knife gate valve is a type of industrial valve that is specifically designed to handle media containing solids, slurry, or thick fluids. It is particularly effective in applications where a tight shut-off is required.

How Does It Work?

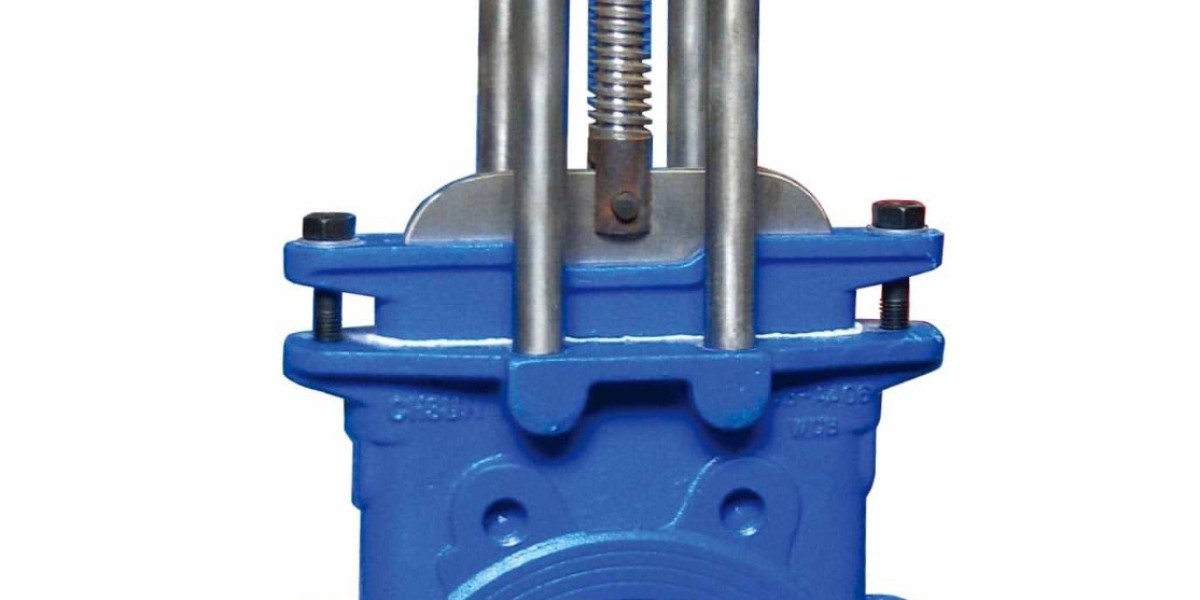

It consists of a sharp-edged gate that can be moved in and out of the flow path. When the valve is open, the gate retracts, allowing the media to pass through. To shut off the flow, the gate is pushed into the flow path, effectively sealing it off. The gate is typically made of materials such as stainless steel or cast iron, ensuring it can withstand the abrasion and wear associated with challenging media.

Functions of Knife Gate Valves

Knife gate valves serve several essential functions in various industrial settings:

1. Isolation:

These valves are excellent at providing a tight seal, effectively isolating sections of a pipeline or system. This isolation is crucial for maintenance, repair, or preventing cross-contamination in different processes.

2. Control:

These valves are used for flow control, allowing operators to regulate the flow rate or shut off the flow completely.

3. Thick Media Handling:

These valves are specifically designed for media that may contain solids, slurry, or high-viscosity fluids. Their sharp-edged gate can cut through and pass this challenging media effectively.

4. Erosion Resistance:

They are built to withstand the erosive effects of abrasive media, making them a reliable choice for applications that involve abrasive materials.

5. Low Pressure Drop:

These valves offer low-pressure drops when fully open, ensuring energy-efficient operation.

6. Bidirectional Flow:

These valves can handle flow in both directions, allowing for versatile use in pipelines.

Applications of Knife Gate Valves

The versatility and robust design of knife gate valves make them suitable for a wide range of applications across various industries, including:

1. Wastewater Treatment:

Knife gate valves are used to handle sewage, sludge, and other challenging media in wastewater treatment plants.

2. Pulp and Paper Industry:

These valves play a vital role in the paper-making process, particularly in handling wood chips, pulp, and paper stock.

3. Mining and Mineral Processing:

In mining operations, knife gate valves are used for slurry transport, tailings management, and other abrasive applications.

4. Chemical Industry:

They are applied in chemical processes that involve the handling of corrosive and abrasive materials.

5. Power Generation:

Knife gate valves are used in coal handling, ash disposal, and other applications in power plants.

6. Food and Beverage Industry:

In the food and beverage industry, these valves handle ingredients like fruit pulp, chocolate, and other viscous substances.

7. Petrochemical Industry:

It play a role in controlling flow and isolation in petrochemical processes.

Conclusion

The knife gate valve, with its sharp-edged gate and robust design, stands as a crucial component in various industrial processes. Its ability to handle abrasive, thick, and challenging media makes it an invaluable asset in applications ranging from wastewater treatment to mining and beyond.

As industries continue to evolve, the knife gate valve maintains its relevance by providing efficient and reliable solutions for fluid and slurry control. Its versatility and unique design make it a dependable choice for engineers and operators seeking to manage and isolate challenging media with precision and confidence.

https://hf-valves.com/knife-gate-valve-its-functions-and-types/