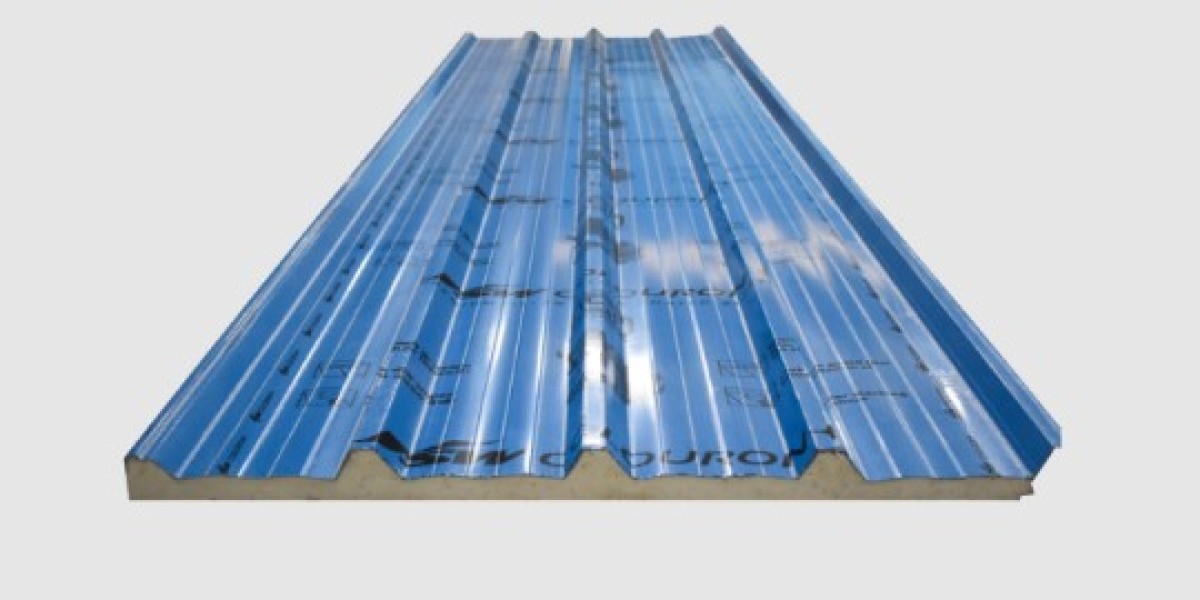

Sandwich PUF (Polyurethane Foam) panels are a remarkable innovation in the construction and insulation industry. These panels consist of three layers - two external layers typically made of metal, and a core layer of PUF insulation. They have gained immense popularity for their versatility, efficiency, and sustainability in various applications:

- Energy-Efficient Insulation:

- SANDWICH PUF PANEL are known for their superior insulation properties. The PUF core acts as a barrier against heat transfer, providing excellent thermal resistance. This makes them ideal for maintaining temperature control within buildings, reducing heating and cooling costs.

- Rapid Construction:

- These panels are designed for quick and easy installation. They can be easily integrated into the construction process, reducing labor and construction time, which is a significant advantage for both residential and commercial projects.

- Versatile Applications:

- Sandwich PUF panels find applications in various sectors, such as cold storage units, industrial warehouses, cleanrooms, and food processing facilities. They are also used for roofing, wall cladding, and partitions in commercial and residential buildings.

- Durable and Lightweight:

- PUF panels are lightweight but incredibly durable. Their durability ensures a longer lifespan, making them a cost-effective choice for long-term projects.

- Sound Insulation:

- In addition to thermal insulation, PUF panels also provide effective sound insulation. This is particularly valuable in applications where noise control is essential, such as in manufacturing units or entertainment venues.

- Fire Resistance:

- Fire-resistant PUF panels are available to meet safety standards and regulations, providing peace of mind for building occupants.

- Moisture Resistance:

- PUF PANEL MANUFACTURER are designed to be moisture-resistant, maintaining their insulation properties even in humid or wet conditions.

- Customization:

- These panels can be customized in terms of thickness, color, and finish, allowing architects and builders to match them to the aesthetic requirements of the project.

- Sustainable Choice:

- Many sandwich PUF panels are manufactured using eco-friendly processes and materials, making them a sustainable and environmentally responsible choice.

- Low Maintenance:

- Once installed, PUF panels require minimal maintenance, reducing operational costs over time.

- Cost Savings:

- Due to their excellent insulation properties, PUF panels contribute to significant energy savings, which can lead to reduced operational expenses.

In conclusion, sandwich PUF panels have transformed the construction and insulation industry. Their exceptional insulation, ease of installation, versatility, durability, and sustainability make them a preferred choice for a wide range of applications. Whether used for industrial warehouses, food storage facilities, or even residential buildings, these panels offer an efficient and cost-effective solution for enhanced energy efficiency and comfort.

Visit our location