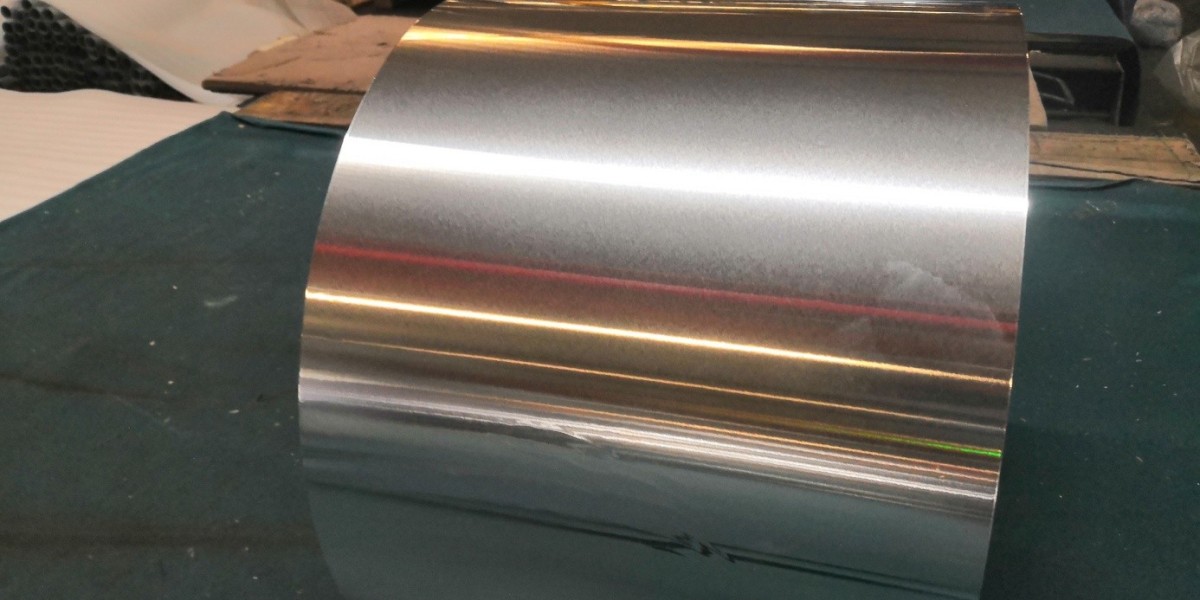

The development of automobile lightweight technology and the necessities of power saving and consumption discount have promoted the a hundred% aluminum alloying of passenger automobile air-conditioning warmth exchanger sheet. Conventional automobile heat exchangers have always used copper alloys, and automobile radiators use composite aluminum foil as opposed to copper alloys, that may reduce the mass by means of 20% to 45%. The common intake of each aluminum radiator is set 2.8kg of Aluminum Foil. The average intake of every car air conditioner is ready 4kg of aluminum tape foil, of which the intake of each condenser is 2.5kg, and the intake of each evaporator is 1.5kg.

The automotive warmth alternate machine consists of components which includes condenser, evaporator, water tank radiator, intercooler, heater, oil cooler, and many others. Brazing composite aluminum warmness exchanger sheet, strip and foil is the middle material for the manufacturing of automotive heat exchangers. Car aluminum heat exchanger consists of aluminum tubes for cooling water and heat sinks for heat dissipation. Aluminum tubes are generally extruded and drawn from 1xxx and 3xxx series aluminum alloys. The warmth dissipation fins are made of composite aluminum foil of 3xxx series, 6xxx collection aluminum alloy core material and 4xxx collection, 7xxx collection aluminum brazing sheet alloy layer.With the substantial boom in the annual output of automobiles, the call for for aluminum heat exchanger sheet and composite aluminum foils has additionally endured to increase. Aluminum-in-region copper for automobile air-conditioning warmth exchangers can not only lessen the load of vehicles, but also lessen manufacturing costs. Consequently, it is of excellent importance to supply excellent and low-value brazing composite aluminum foils for car air conditioners.

Search

Popular Posts