In the realm of manufacturing and machining, precision and efficiency are paramount. Industries across India have recognized the significance of utilizing advanced technologies and machinery to enhance their production processes. One such crucial piece of equipment is the End Milling Machine.

Understanding End Milling Machines

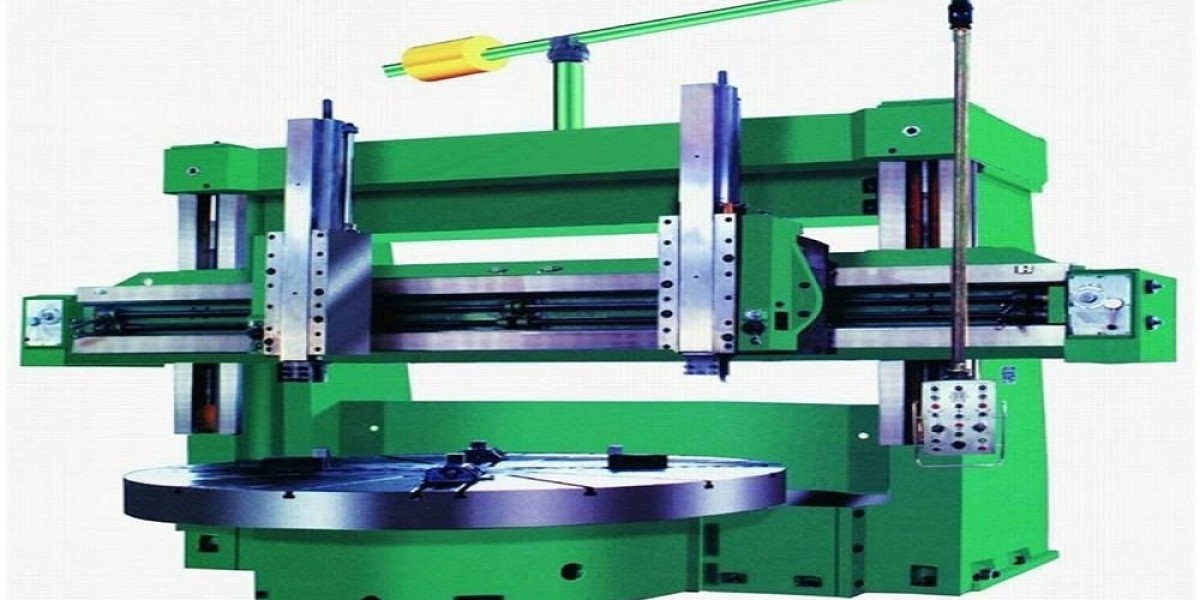

End Milling Machines are a vital component in the manufacturing industry, particularly in the metalworking and woodworking sectors. These machines are used for cutting, shaping, and contouring various materials, such as metal, wood, plastic, and composites, with utmost precision. They are instrumental in creating complex and intricate designs, making them indispensable in industries like aerospace, automotive, and furniture manufacturing.

Evolution of End Milling Machines in India

The journey of End Milling Machines in India has been marked by significant advancements and innovations over the years.

Manual End Milling Machines:

In the early days of manufacturing in India, End Milling Machines were primarily operated manually. Craftsmen would use these machines to create basic designs and shapes, relying on their skill and expertise. While these machines were effective to some extent, they were limited in terms of precision and production capacity.

Introduction of CNC Technology:

The turning point in the evolution of End Milling Machines in India came with the introduction of Computer Numerical Control (CNC) technology. CNC End Milling Machines brought automation and precision to a whole new level. These machines could execute complex milling tasks with incredible accuracy, making them a game-changer in the manufacturing industry.

High-Speed Machining:

The latest trend in the End Milling Machine industry is high-speed machining. These machines are equipped with advanced tooling and cutting strategies that enable them to operate at significantly higher speeds while maintaining precision. This translates to reduced production times and increased efficiency.

Improved Quality:

CNC Horizontal Boring Machine in India have raised the bar in terms of quality and precision. Manufacturers can produce intricate and accurate components, leading to superior product quality and consistency.

Increased Productivity:

Automation and high-speed machining have drastically increased production rates. This efficiency has made Indian manufacturers more competitive on a global scale.

Cost Efficiency:

While the initial investment in advanced End Milling Machines may be significant, the long-term cost savings in terms of reduced labor and improved productivity are substantial.

Diverse Applications:

End Milling Machines are now used across various industries, ranging from aerospace and automotive to furniture and construction. Their versatility has opened up new opportunities and markets for Indian manufacturers.

Conclusion

The evolution of End Milling Machines in India is a testament to the country's commitment to technological advancement and manufacturing excellence. From manual operations to CNC automation and high-speed machining, these machines have come a long way in improving quality, productivity, and versatility in manufacturing. As technology continues to evolve, Vertical Turning Lathe in India are likely to play an even more pivotal role in shaping the future of manufacturing in India.