Roofing sheet product manufacturing is a critical industry that plays a pivotal role in constructing durable and reliable roofs. This article explores the key aspects of manufacturing roofing sheets, emphasizing quality and innovation as central themes in the production process.

1. Material Selection

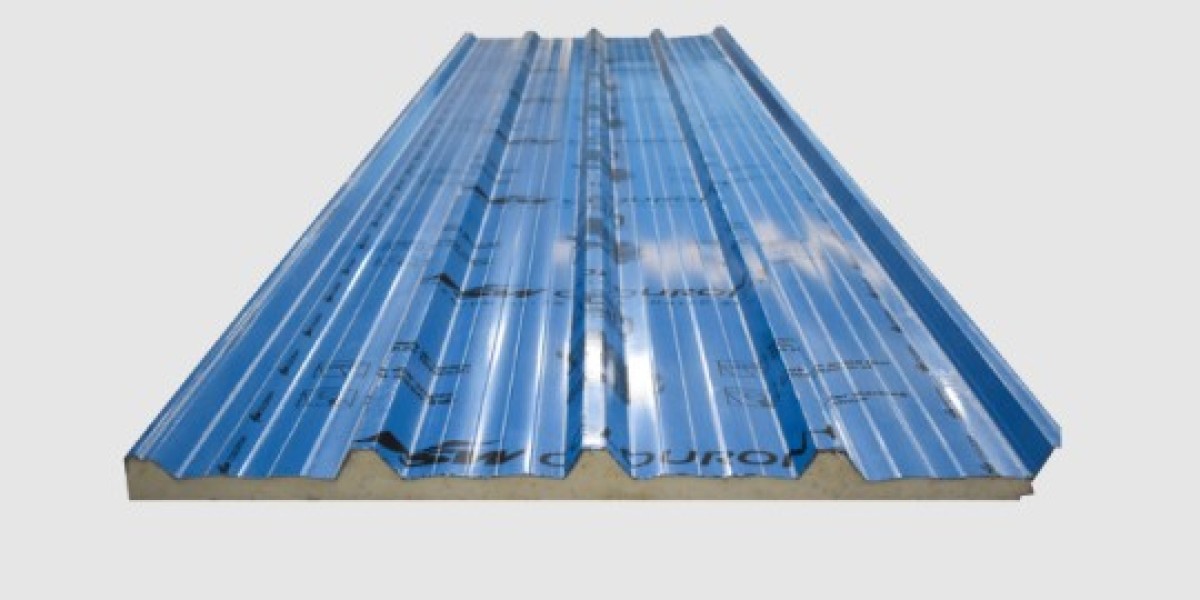

The foundation of any exceptional Roofing manufacturers begins with material selection. Manufacturers must choose high-quality materials such as steel, aluminum, or specialized alloys to ensure longevity and resilience. These materials must also meet industry standards for corrosion resistance and structural integrity.

2. Roll Forming Process

The roll forming process is at the heart of roofing sheet manufacturing. This method involves passing metal coils through a series of rollers to create the desired profile. Precise engineering and calibration of these machines are vital to produce consistent, uniform sheets that fit seamlessly on roofs.

3. Coating and Finish

To enhance durability and aesthetics, roofing sheets undergo coating and finishing processes. This can include galvanization, paint application, or other protective coatings. Manufacturers need to employ advanced techniques to ensure that these coatings adhere securely and resist weathering.

4. Quality Control

Quality control is non-negotiable in roofing sheet manufacturing. Stringent inspections and tests are carried out to verify dimensional accuracy, coating adhesion, and material integrity. Continuous monitoring and adherence to quality standards are essential to delivering reliable products.

5. Innovation and Sustainability

In today's roofing sheet manufacturing landscape, innovation and sustainability are driving forces. Manufacturers are exploring eco-friendly materials and energy-efficient production methods to reduce their carbon footprint. Moreover, advancements in digital design and simulation tools are enabling the creation of increasingly efficient and cost-effective roofing solutions.

6. Customization and Customer Satisfaction

Meeting the diverse needs of customers is paramount. Roofing sheet manufacturers offer customization options, including various profiles, colors, and sizes, to cater to different architectural styles and preferences. Ensuring customer satisfaction is essential for building trust and reputation in the industry.

Conclusion

In the roofing sheet product manufacturing industry, the pursuit of excellence in material selection, production processes, and innovation is essential. Manufacturers must prioritize quality and customer satisfaction to provide roofing solutions that protect and enhance buildings for years to come. With these principles in mind, roofing sheet products can continue to evolve and meet the demands of an ever-changing market.

For more info. visit us: