Unlock the Secrets to Effortless Maintenance: Discover Essential Spare Parts and Expert Tips!

In the world of machinery and equipment, maintenance is paramount. It ensures that your devices operate at peak efficiency and have a longer lifespan. One crucial element of effective maintenance is the use of spare parts; these components are vital for replacing worn-out or faulty items, thereby keeping your machinery running smoothly. Without the right spare parts, even the most robust machines can falter, leading to costly downtime and repairs. This article will delve into essential spare parts, their specifications, and provide expert maintenance tips to help you achieve effortless upkeep of your machinery.

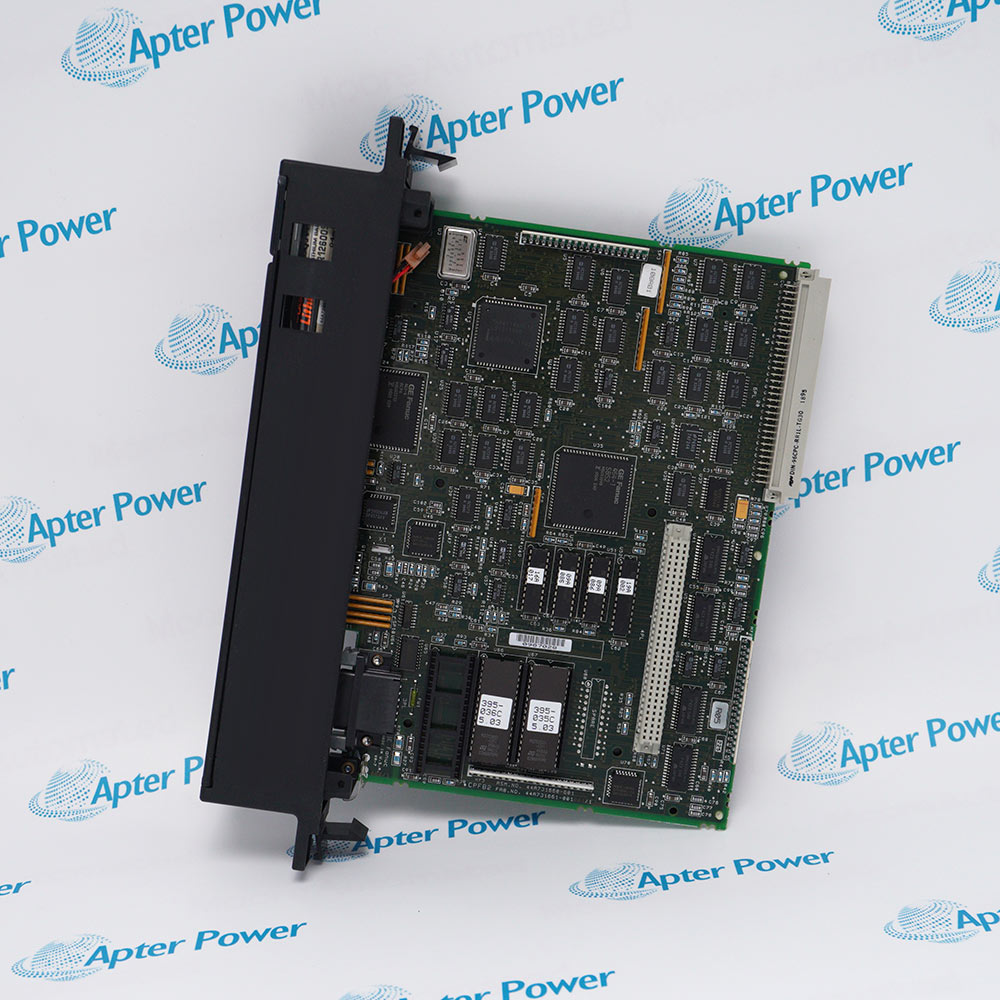

Understanding General Electric Spare Parts

General electric spare parts refer to the components designed to replace or support the functionality of various electric equipment and machinery. These parts play a significant role in maintenance, ensuring that equipment operates efficiently and effectively. Spare parts can be categorized into several types: original equipment manufacturer (OEM) parts, aftermarket parts, and refurbished parts. OEM parts are made by the original manufacturer and are known for their quality and reliability. Aftermarket parts may be made by third-party manufacturers and can often provide a cost-effective alternative. Refurbished parts are pre-owned components that have been restored to working order. Understanding these categories is crucial for making informed decisions during maintenance.

Essential Spare Parts for Efficient Maintenance

To maintain machinery effectively, several essential spare parts are necessary. First, consider the bearings. These components reduce friction between moving parts, ensuring smooth operation. They come in various sizes and materials, depending on the machinery's requirements. Next, seals and gaskets are crucial for preventing leaks and protecting internal mechanisms from dust and debris. A personal anecdote from a friend who runs a small manufacturing unit highlights the importance of keeping a stock of seals on hand; a minor leak led to major operational delays when replacements weren’t readily available. Additionally, belts and chains are vital for transferring power between components. Over time, these parts can wear out, leading to reduced efficiency or even breakdowns. Lastly, electrical components such as fuses and circuit breakers are critical for safety and functionality, protecting the equipment from electrical overloads. Each of these parts plays a pivotal role in ensuring that machinery operates smoothly and efficiently.

Tips for Identifying and Sourcing Spare Parts

Identifying the right spare parts for your machinery can seem daunting, but with a systematic approach, it becomes manageable. Start by consulting the equipment’s manual, which typically lists the exact specifications for necessary spare parts. If the manual is unavailable, examining the components for part numbers and manufacturer details can also be helpful. When sourcing spare parts, consider both local suppliers and online resources. Local suppliers can provide immediate access to parts, saving time and reducing downtime. Online platforms often offer a wider selection and competitive pricing. My friend, who faced a long wait for a part from a local shop, discovered that ordering online not only saved him money but also provided a faster delivery option. Always verify the credibility of the source to ensure you receive quality components.

Maintenance Tips for Longevity

Additionally, implementing effective maintenance measures is crucial for extending the lifespan of equipment. Daily checks for cleanliness and condition are essential; overlooked components can lead to unexpected breakdowns. Establishing a regular maintenance schedule should include weekly inspections, lubricating moving parts, and replacing worn-out parts promptly. Such practices enhance the functionality of machinery, significantly reducing the likelihood of unexpected costs associated with repairs. Your friend found that keeping track of maintenance practices not only helped in extending life but also ensured smoother operations.

Summary of Key Maintenance Insights

In summary, understanding spare parts and implementing effective maintenance strategies are crucial for achieving effortless upkeep of your machinery. By familiarizing yourself with the types of spare parts available, recognizing the essential components needed for maintenance, and employing expert tips for sourcing and caring for your equipment, you can enhance operational efficiency and reduce downtime. Taking proactive steps in your maintenance practices will not only save you time and money but also ensure that your machines remain reliable for years to come. Embrace these strategies and unlock the full potential of your machinery!