A hydraulic pump is a vital component of any hydraulic system. It is responsible for moving fluid through the system and providing the necessary pressure to operate hydraulic cylinders and motors. When choosing a hydraulic pump, it is important to consider the type of application you will be using it for.

In hydraulic systems, there are two key components that work together to create the energy that moves parts of the system.

The first is the hydraulic pump. The second is the reservoir. The hydraulic pump is responsible for moving fluid from the reservoir into the system.

The reservoir stores fluid and helps to keep the system pressurized. It is important to choose the correct hydraulic pump for your application.

There are many different types of hydraulic pumps available on the market today. Different types of pumps are designed for different applications.

Some pumps are designed for high-pressure applications, while others are designed for low-pressure applications.

It is important to consult with a hydraulic engineer to determine which type of pump is best suited for your application.

A hydraulic pump is considered a positive displacement pump because it creates a certain amount of flow per revolution.

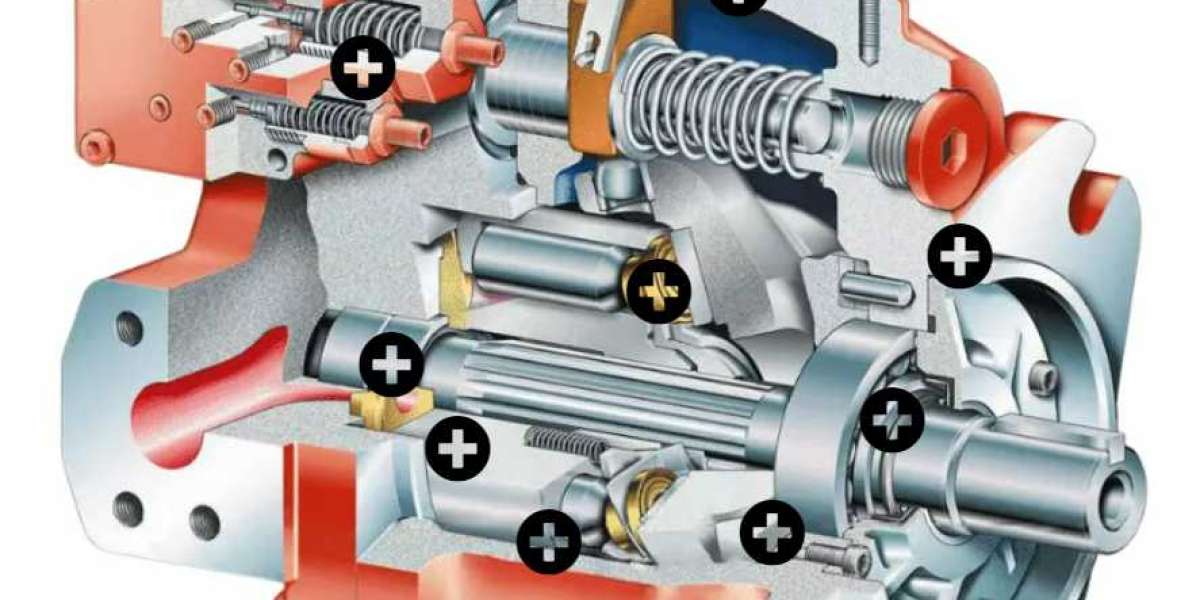

There are three main types of hydraulic pumps: gear, vane, and piston. Each type has its own advantages and disadvantages, so it's important to pick the right one for your application.

Gear pumps are the most common type of hydraulic pump. They're simple and reliable, and they can handle a wide range of pressures. However, they're not as efficient as other types of pumps, so they can generate a lot of heat.

Vane pumps are more efficient than gear pumps, but they can't handle as much pressure. They're often used in lighter-duty applications such as power steering systems.

Piston pumps are the most efficient type of hydraulic pump, but they can only be used in low-pressure applications.

Positive displacement pumps are further categorized based on the design of their internal components and the way they displace fluid.

The most common type of positive displacement pump is the reciprocating pump. Reciprocating pumps use a piston or plunger to draw fluid into a chamber and then force it out. The reciprocating motion of the piston allows the pump to draw fluid from a suction port and discharge it at a higher pressure through a delivery port.

Another common type of positive displacement pump is the rotary pump. Rotary pumps displace fluid by rotating internal components, such as gears or vanes. The rotation creates an cavity that draws in and expels fluid.

Hydraulic pumps are used in a variety of applications, such as construction, automotive and manufacturing. When selecting a hydraulic pump, it is important to consider the needs of your application. Factors to consider include flow rate, pressure, power source and duty cycle.

The type of fluid used in your system also plays a role in determining which pump will best meet your needs.

If you're using a water-based fluid, then you'll want to choose a pump that's specifically designed for that type of fluid. There are different types of hydraulic pumps available on the market, so it's important to do your research and find the one that will work best for your specific application.

If you're using an oil-based fluid, then you'll want to choose a pump that's designed for that type of fluid. Again, there are different types of hydraulic pumps available, so it's important to do your research and find the one that will work best for your specific application.

Once you've determined the type of fluid you're using, you can start narrowing down your options and choosing the best hydraulic pump for your needs.

Even though certain types of fluids can be compatible with multiple pumps, some are better suited for specific applications.

There are many different types of hydraulic pumps on the market today, each designed for specific applications. Choosing the right pump for your application can be a daunting task. Here are a few tips to help you choose the best hydraulic pump for your needs.

First, consider the type of fluid you will be using. Some fluids are compatible with multiple types of pumps, while others are better suited for specific types of pumps. If you are not sure which type of fluid you will be using, consult with a hydraulic expert.

Next, consider the pressure and flow requirements of your application. Hydraulic pumps come in a variety of pressure and flow ratings. Choose a pump that can meet or exceed the pressure and flow requirements of your application.

Finally, consider the environment in which the pump will be used. Some pumps are designed for use in harsh environments, while others are not. Make sure to choose a pump that is designed for use in the environment in which it will be used.

By following these tips, you can be sure to choose the best hydraulic pump for your needs.