In the world of manufacturing, precision and efficiency are more than just buzzwords—they are the lifeblood of every successful production line. Industries from aerospace to medical devices depend on components that must meet extremely tight tolerances, and in many cases, those components are produced using CNC Turning. This technology combines advanced computer control with high-speed machining to create parts that are both accurate and consistent, no matter the volume.

What is CNC Turning?

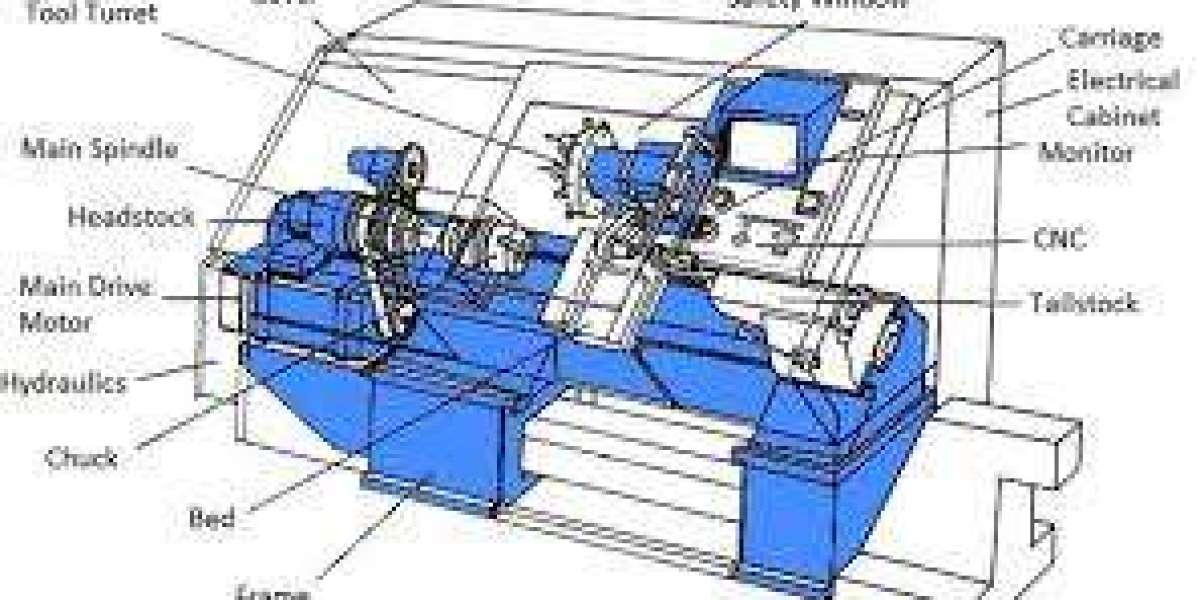

CNC Turning is a subtractive manufacturing process in which a workpiece—often a rod or cylinder of metal or plastic—is rotated while a stationary cutting tool removes material to form the desired shape. The “CNC” stands for Computer Numerical Control, which means the cutting tool’s movements are guided by a precise digital program rather than manual operation. This ensures repeatable quality and the ability to produce parts with incredibly fine tolerances.

While traditional lathes require skilled operators to manually control feeds, speeds, and depth of cut, CNC Turning automates these functions, allowing for higher productivity, more complex designs, and reduced human error.

Why CNC Turning is a Game-Changer

Manufacturers today operate in a fast-paced environment where product development cycles are shorter, customers expect faster delivery, and quality requirements have never been higher. CNC Turning meets these demands by offering:

High Precision: Capable of achieving tolerances as tight as ±0.005 mm.

Repeatability: Producing identical parts across small or large production runs.

Speed: Significantly faster than manual turning without sacrificing accuracy.

Versatility: Works with metals, alloys, and engineering plastics.

Cost-Efficiency: Less material waste, fewer errors, and faster turnaround times.

These advantages make it a preferred choice for industries such as automotive, aerospace, electronics, and industrial equipment manufacturing.

The CNC Turning Process at Yicen Precision

At Yicen Precision, the CNC Turning process is designed for maximum efficiency without compromising quality. It begins with a careful review of the client’s CAD files. This stage allows engineers to identify opportunities to simplify designs, choose the right materials, and optimize the machining process.

Once the design is finalized, the programming stage begins. Advanced CAM (Computer-Aided Manufacturing) software translates the 3D model into precise tool paths. These instructions are loaded into multi-axis CNC turning centers, which can perform multiple operations—such as drilling, boring, threading, and grooving—in a single setup.

After machining, each part undergoes strict quality control. Using advanced metrology equipment like coordinate measuring machines (CMMs), inspectors verify dimensions, tolerances, and surface finishes before parts are shipped to the customer.

Applications Across Industries

The versatility of CNC Turning makes it applicable to a wide range of industries:

Aerospace: Precision shafts, bushings, and hydraulic fittings for high-performance aircraft.

Automotive: Engine parts, transmission shafts, and suspension components.

Medical: Surgical tools, implants, and diagnostic device components.

Electronics: Miniature housings, connectors, and precision fasteners.

Energy: Components for turbines, pumps, and industrial valves.

In each of these fields, quality and reliability are paramount—and CNC Turning delivers both.

Best Practices for CNC Turning Design

To ensure the most efficient and cost-effective results, engineers should follow these guidelines when designing parts for CNC Turning:

Use Standard Sizes: Selecting standard hole diameters, thread sizes, and tolerances can reduce machining time and costs.

Avoid Unnecessary Complexity: While CNC Turning can produce intricate shapes, unnecessary complexity may increase production costs.

Consider Material Properties: Different materials respond differently to machining, so choose the right one for your application.

Specify Surface Finish Early: Whether you need a mirror polish or a rougher texture, specifying it upfront helps avoid rework.

Maintain Reasonable Wall Thickness: Very thin walls can lead to deformation during machining.

The Yicen Precision Difference

What sets Yicen Precision apart is the combination of advanced technology, skilled professionals, and a dedication to customer satisfaction. Their state-of-the-art equipment includes high-speed, multi-axis CNC lathes capable of producing parts with exceptional accuracy. The team’s experience ensures that every project, from prototype to high-volume production, is handled with the same attention to detail.

Clients also benefit from Yicen Precision’s ability to work with a broad range of materials, including aluminum, stainless steel, brass, titanium, and engineering plastics. This versatility allows them to serve diverse industries without compromising quality.

The Future of CNC Turning

Technology in CNC Turning continues to evolve. Automation is becoming more sophisticated, enabling unattended machining for extended periods, which reduces labor costs and increases output. Tooling advancements are allowing for faster speeds, longer tool life, and even greater precision. Integration with digital manufacturing systems means that production can be monitored and adjusted in real time, ensuring consistent quality and shorter lead times.

As global manufacturing demands grow, CNC Turning will remain an indispensable technology, continually adapting to meet the needs of modern production.

Conclusion

Whether you’re producing a single prototype or thousands of parts, CNC Turning offers the precision, efficiency, and reliability needed to meet today’s manufacturing challenges. By partnering with experts like Yicen Precision, companies can be confident that their components will be produced to exact specifications, delivered on time, and ready for performance in the real world.

In an industry where even the smallest deviation can lead to costly failures, choosing the right CNC Turning service isn’t just important—it’s essential.