Report Overview:

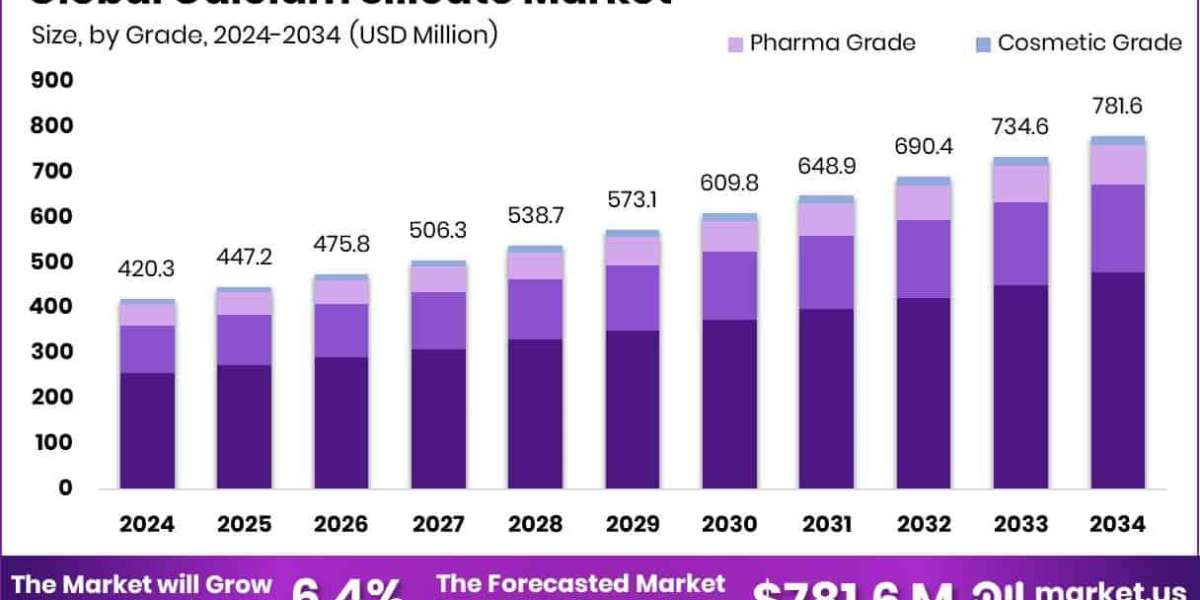

The Global Calcium Silicate Market was valued at around USD 420.3 million in 2024 and is expected to grow steadily to approximately USD 781.6 million by 2034, with a CAGR of 6.4% during the forecast period. This growth is largely driven by rising applications in construction and industrial insulation where safety, fire resistance, and thermal protection are essential. Industrial-grade calcium silicate holds the lion’s share of 61.3%, thanks to its wide usage in power plants, manufacturing, and oil & gas. Meanwhile, low-density variants dominate in lightweight applications, especially where easy handling is preferred. The construction sector alone accounts for 43.5% of the market demand, particularly in fire-rated panels, ceiling tiles, and eco-friendly insulation. Regionally, North America leads with a 43.8% share, fueled by strict building safety codes and advanced infrastructure requirements.

Calcium silicate is a durable, lightweight insulation material made from limestone and silica. It is especially useful for thermal insulation in hot industrial environments and fireproofing in buildings. The product’s reliability in extreme heat and resistance to moisture makes it ideal for multiple sectors, including construction, power generation, and oil refining. Demand continues to rise due to stricter fire safety regulations and growing energy efficiency needs in both developed and emerging economies. Low-density calcium silicate boards, which are easier to install, are gaining traction for commercial and residential buildings. On the other hand, industrial-grade variants continue to find favor in energy-intensive industries. Aside from insulation, calcium silicate is also used in food and pharma as an anti-caking agent, thanks to its non-toxic properties. This shows the product's versatility across very different industries and highlights strong growth prospects, especially with ongoing advancements in material engineering.

Key Takeaways

The calcium silicate market is set to increase from USD 420.3 million (2024) to USD 781.6 million by 2034, at a 6.4% CAGR.

Industrial-grade calcium silicate leads the market with a 61.3% share, preferred in high-heat environments.

Low-density variants are popular, accounting for 47.1% share, as they’re easier to handle and install.

The construction industry makes up 43.5% of the demand, with rising use in fire-resistant panels and insulation.

North America dominates the market, holding a 43.8% share, thanks to advanced building standards and awareness.

Download Exclusive Sample Of This Premium Report: https://market.us/report/global-calcium-silicate-market/free-sample/

Key Market Segments:

By Grade

- Industrial Grade

- Food Grade

- Pharma Grade

- Cosmetic Grade

By Product Type

- Low Density

- Medium Density

- High Density

By End-Use

- Construction

- Pharmaceutical

- Food and Beverages

- Others

DORT Analysis

Drivers

The growing need for effective insulation in construction and industrial settings is pushing demand for calcium silicate. Its fire-resistant and heat-resistant qualities make it a preferred choice over traditional materials. Increasing infrastructure development and urbanization globally are fueling its use. In addition, evolving safety regulations across regions are promoting the shift toward non-combustible, durable insulation materials like calcium silicate.

Opportunities

Rapid development in Asia-Pacific, especially in India and China, creates promising prospects for market expansion. New uses in the food and pharmaceutical sectors are emerging as niche growth areas. Companies exploring innovations like nano enhanced calcium silicate or hybrid composites can enter premium markets. The clean energy sector, particularly solar power, also needs efficient thermal insulation. Customized solutions in partnership with manufacturers offer room for long-term contracts.

Restraints

Cheaper alternatives like fiberglass and mineral wool limit the adoption of calcium silicate in cost-conscious projects. Its production and installation costs can be higher, making it less appealing where budget is a constraint. Concerns related to dust inhalation and skin irritation have prompted regulatory guidelines, adding operational hurdles. Furthermore, limited awareness in developing regions is slowing its potential growth.

Trends

There’s rising demand for lightweight, low-density insulation boards for easy installation. Industrial-grade insulation remains vital in oil, gas, and manufacturing due to high heat resistance. Use in pharma and food continues to grow, where it acts as a safe anti-caking agent. Asia-Pacific shows the fastest growth rate, while Europe is advancing due to strict building codes. Material innovation, including moisture-resistant coatings, is also gaining popularity.

Market Key Players:

- American Elements

- Promat International NV

- Morgan Advanced Materials

- Prochem Inc.

- Spectrum Chemical Manufacturing Corp.

- Materion Corporation

- Associated Ceramics and Technology Inc.

- Mil-Spec Industries Corporation

- Pyrotek

- Skamol

- ZIRCAR CERAMICS