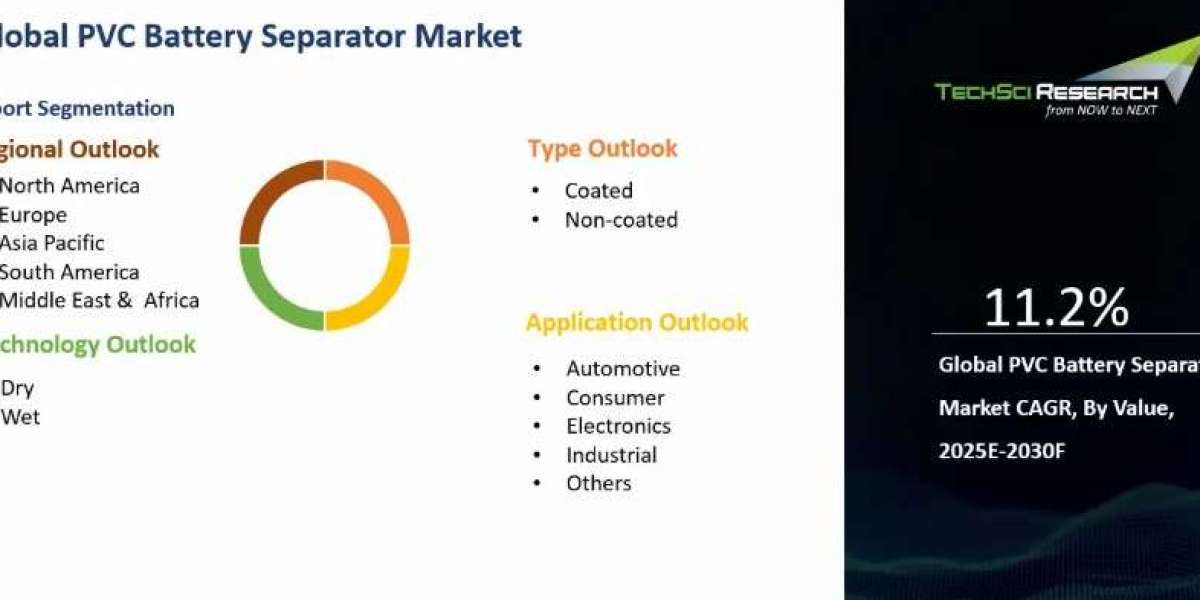

According to the TechSci Research report titled “PVC Battery Separator Market - Global Industry Size, Share, Trends, Competition Forecast & Opportunities, 2030F”, the global PVC Battery Separator Market was valued at USD 7.4 billion in 2024 and is projected to reach USD 14.1 billion by 2030, growing at a CAGR of 11.2% during the forecast period. The market’s expansion is primarily driven by increasing demand for electric vehicles (EVs), especially two-wheelers and low-speed electric vehicles, along with growing interest in renewable energy storage systems.

Rising Demand from Electric Two-Wheelers and Rural Electrification

One of the primary factors driving the growth of the PVC battery separator market is the rising adoption of electric two-wheelers and low-speed EVs, particularly in developing countries. These vehicles commonly use cost-effective lead-acid batteries, which continue to dominate many emerging markets due to their affordability, simplicity, and ease of recycling. PVC separators are widely used in these batteries because of their compatibility and low production cost, making them a preferred choice for mass-market applications.

Additionally, the expansion of rural electrification programs in Asia and Africa has significantly increased the demand for off-grid energy storage solutions. In these areas, batteries are crucial for providing consistent and reliable power, especially where grid infrastructure is limited or unreliable. PVC battery separators, as a core component in lead-acid batteries, are benefiting from this trend. Their cost-effectiveness and reliability make them ideal for deployment in rural or remote settings.

Dependence on Lead-Acid Batteries in Critical Infrastructure

Another critical driver of market growth is the reliance on lead-acid batteries in sectors such as telecom and data centers, particularly in regions that experience frequent power outages or unstable grid conditions. As global connectivity expands and data consumption rises, the need for uninterrupted power in these infrastructures becomes paramount. Lead-acid batteries offer a reliable and economical backup power solution, and PVC separators are essential for maintaining battery performance, ensuring proper ion flow, and preventing internal short circuits.

Push for Localization and Sustainability

Manufacturers are increasingly focusing on localizing production to reduce costs and minimize dependence on imports. This shift is especially significant in emerging economies where battery demand is growing, and local supply chains are being developed to support domestic manufacturing capabilities. As a result, there is rising demand for locally sourced PVC battery separators, which further accelerates regional market development.

Furthermore, the global emphasis on sustainability and the circular economy supports continued reliance on lead-acid batteries, largely because they are highly recyclable. The recyclability of these batteries reinforces the demand for PVC separators, which are integral to their design. As environmental regulations tighten and recycling incentives grow, PVC separators are likely to maintain their importance in battery manufacturing.

Market Segmentation by Type: Non-Coated PVC Separators Dominate

Based on type, the non-coated segment emerged as the dominant category in the global PVC battery separator market in 2024 and is expected to maintain its lead through 2030. This segment is widely used in traditional lead-acid batteries, particularly in applications where cost sensitivity is a major factor.

Non-coated PVC separators are a preferred choice in automotive aftermarket batteries, industrial backup systems, and low-voltage energy storage solutions. Their design eliminates the need for surface treatments or coatings, which significantly reduces production costs. Despite their simplicity, these separators provide the essential functions of ion transport, electrical insulation, and short-circuit prevention.

These separators are especially effective in automotive SLI (starting, lighting, and ignition) batteries, which do not require high-end performance but need dependable operation under standard conditions. They offer sufficient mechanical stability, chemical resistance to acidic environments, and ease of processing—qualities that make them ideal for mass production and deployment in cost-conscious markets.

In countries across Asia-Pacific, Latin America, and Africa, manufacturers continue to use non-coated PVC separators due to their affordability and proven field performance. The presence of established manufacturing infrastructure and abundant raw material supply supports the segment’s continued dominance.

While coated separators—often used in lithium-ion batteries—are gaining traction for high-performance applications such as EVs and grid-scale energy storage, they involve higher production costs. For this reason, the non-coated PVC separator segment remains the backbone of traditional lead-acid battery applications, where cost, reliability, and scalability are top priorities.

Browse over XX market data Figures spread through XX Pages and an in-depth TOC on the "Global PVC Battery Separator Market"

https://www.techsciresearch.com/report/pvc-battery-separator-market/30211.html

Regional Insights: Asia-Pacific Leads Growth

Asia-Pacific is emerging as the fastest-growing regional market for PVC battery separators. Countries such as China, India, Japan, and various Southeast Asian nations are experiencing rapid expansion in sectors like automotive, industrial storage, and renewable energy. The widespread use of lead-acid batteries in these areas continues to fuel demand for PVC separators.

China, the world’s leading battery production hub, is central to regional growth due to its significant investment in battery manufacturing and advanced energy solutions. The country's vast EV industry, solar energy expansion, and telecom infrastructure all rely heavily on battery storage—making PVC separators a vital component of this supply chain.

In India, increasing demand for inverter and replacement batteries—particularly in rural and semi-urban markets—drives additional growth. Power backup solutions for households and businesses are essential in many parts of the country where grid power is either unstable or unavailable, making lead-acid batteries with PVC separators indispensable.

The region also benefits from a robust ecosystem of raw material suppliers, skilled labor, and manufacturing facilities that can support the high-volume production required for PVC separators. Government initiatives such as India’s Production-Linked Incentive (PLI) scheme and China’s clean energy storage policies are further stimulating investments in local battery production, enhancing regional competitiveness.

Conclusion

The global PVC Battery Separator Market is poised for substantial growth over the forecast period, driven by strong demand for lead-acid batteries in electric mobility, telecom infrastructure, rural electrification, and backup power solutions. With non-coated PVC separators maintaining a dominant share due to their affordability and widespread use in cost-sensitive markets, and Asia-Pacific leading the global charge, the market is expected to witness robust and sustained expansion through 2030.

Key market players in the PVC Battery Separator Market are:

Entek International LLC

Daramic, LLC (Asahi Kasei Corporation)

Toray Industries, Inc.

Sumitomo Chemical Co., Ltd.

UBE Corporation

Zhongke Science & Technology Co., Ltd.

Shanghai Energy New Materials Technology Co., Ltd. (SEMCORP)

Sinoma Science & Technology Co., Ltd.

Download Free Sample Report

https://www.techsciresearch.com/sample-report.aspx?cid=30211

Customers can also request for 10% free customization on this report.

“The global PVC battery separator market presents significant growth opportunities driven by rising demand for cost-effective energy storage solutions in emerging economies. Expanding automotive and industrial sectors, particularly in Asia-Pacific, Latin America, and Africa, are fueling the use of lead-acid batteries, where PVC separators are widely applied. Additionally, the growing need for reliable backup power in telecom, healthcare, and renewable energy sectors supports market expansion.

Advancements in PVC separator technology, such as improved porosity and thermal stability, also open new application avenues. Moreover, localization of production and government incentives for domestic battery manufacturing further enhance the market’s future growth potential.” said Mr. Karan Chechi, Research Director of TechSci Research, a research-based global management consulting firm.

“PVC Battery Separator Market – Global Industry Size, Share, Trends, Opportunity, and Forecast, Segmented By Type (Coated, Non-coated), By Technology (Dry, Wet), By Application (Automotive, Consumer, Electronics, Industrial, Others), By Region &Competition, 2020-2030F” has evaluated the future growth potential of PVC Battery Separator Market and provides statistics & information on market size, structure, and future market growth. The report intends to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides the report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in PVC Battery Separator Market.

Contact

TechSci Research LLC

420 Lexington Avenue,

Suite 300, New York,

United States- 10170

M: +13322586602

Email: [email protected]

Website: https://www.techsciresearch.com