The reciprocating pump market plays a vital role in the global industrial landscape, serving a wide array of sectors including oil and gas, chemical processing, water and wastewater treatment, power generation, and mining. Known for their ability to deliver precise, high-pressure flow control, reciprocating pumps are indispensable in applications that demand accuracy and durability. This summary provides an overview of the current market status, key growth drivers, challenges, and future prospects for the reciprocating pump industry.

Market Overview

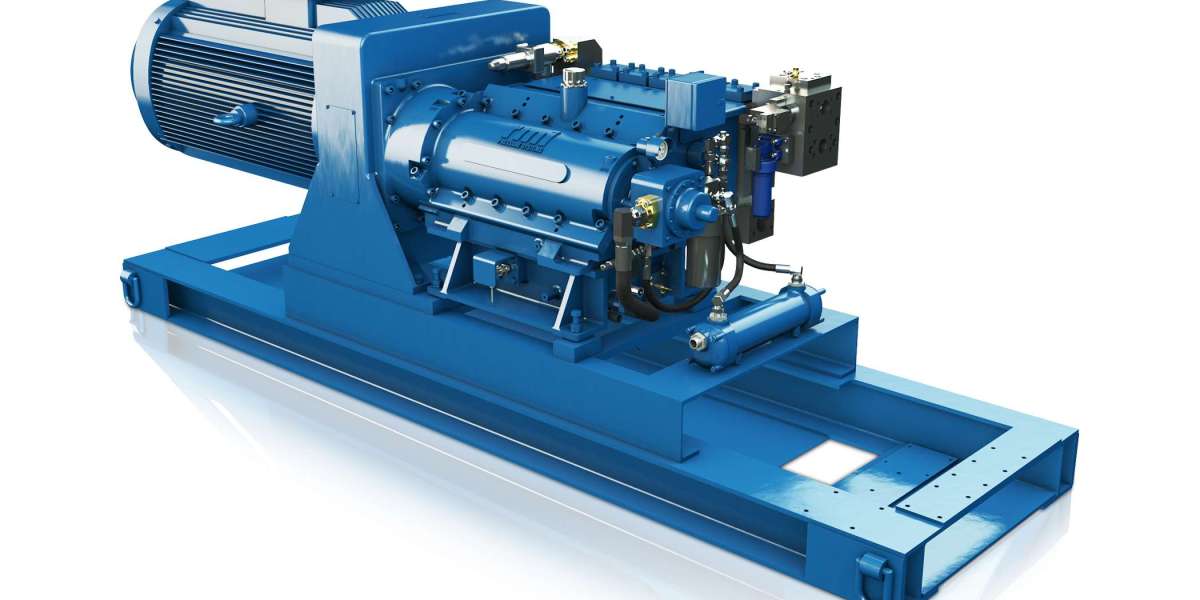

Reciprocating pumps operate on a positive displacement principle, where fluid is drawn into a chamber and then expelled by the movement of a piston or diaphragm. Their design allows them to handle highly viscous fluids, abrasive materials, and operate at high pressures, making them ideal for critical industrial processes.

Globally, the market has been experiencing steady growth, driven by industrial expansion, infrastructure development, and increasing demand for efficient fluid handling solutions. The Asia-Pacific region leads in market growth due to rapid urbanization, industrialization, and energy infrastructure projects, while North America and Europe remain mature markets with steady demand supported by modernization and maintenance activities.

Key Growth Drivers

Several factors are propelling the growth of the reciprocating pump market:

Industrial Expansion and Infrastructure Development

Rapid growth in industries such as oil and gas, chemicals, and mining continues to fuel demand. Projects in upstream and downstream oil extraction rely heavily on reciprocating pumps for chemical injection, enhanced oil recovery, and other high-pressure tasks. Similarly, chemical plants require pumps capable of handling corrosive and viscous fluids with precision.Water and Wastewater Treatment Needs

Increasing population, urbanization, and environmental regulations are driving investments in water management infrastructure globally. Reciprocating pumps are widely used for chemical dosing and sludge handling in treatment plants, which supports sustainable water usage and pollution control.Technological Advancements

Manufacturers are integrating smart technologies into reciprocating pumps, including IoT-enabled sensors and real-time monitoring systems. These features enhance reliability, reduce downtime through predictive maintenance, and optimize energy consumption—making the pumps more attractive to modern industries focused on operational efficiency.Energy Efficiency and Sustainability Focus

With rising energy costs and stricter environmental regulations, there is a growing demand for energy-efficient pumping solutions. Advances in hydraulic design, materials, and control systems are improving the overall efficiency of reciprocating pumps, aligning them with sustainability goals and broadening their market appeal.

Market Challenges

Despite promising growth, the reciprocating pump market faces several challenges:

High Initial Cost and Maintenance

Reciprocating pumps often have higher upfront costs compared to centrifugal pumps and require more complex maintenance due to their moving parts. This can deter small-scale industries or cost-sensitive buyers from adoption.Competition from Alternative Technologies

Centrifugal and rotary pumps are widely used alternatives that offer advantages in low-pressure, high-flow applications. As these technologies evolve, they sometimes encroach upon markets traditionally dominated by reciprocating pumps.Supply Chain and Raw Material Volatility

Fluctuations in raw material prices and recent supply chain disruptions have affected manufacturing costs and delivery times, introducing uncertainties that can impact procurement and project schedules.

Regional Insights

The Asia-Pacific region dominates the reciprocating pump market’s growth trajectory, driven by large-scale infrastructure projects, rising energy demand, and industrial expansion in countries like China, India, and Southeast Asia. North America maintains steady demand fueled by shale gas development, chemical manufacturing, and water infrastructure upgrades. Europe, while a mature market, is evolving under the influence of strict environmental policies and an emphasis on energy-efficient technologies.

Emerging economies in Latin America, Africa, and the Middle East are gaining traction as new oil, gas, mining, and industrial projects come online, presenting significant untapped opportunities for reciprocating pump manufacturers and suppliers.

Future Outlook

The future of the reciprocating pump market looks promising, with sustained growth expected over the next decade. Key trends shaping this outlook include:

Digitalization and Smart Pumping Solutions

The adoption of smart technologies will accelerate, with pumps increasingly equipped with sensors for performance tracking, fault detection, and remote monitoring. This will improve operational efficiency and lower maintenance costs.Expansion into New Applications

Industries such as pharmaceuticals, food and beverage, and biotechnology are exploring reciprocating pumps for precise dosing and handling of sensitive fluids, opening new market avenues.Emphasis on Sustainability

Environmental regulations and corporate sustainability initiatives will continue to drive demand for energy-efficient and environmentally friendly pumping solutions, encouraging further innovation.Aftermarket and Service Growth

As installed equipment ages, aftermarket services including repair, maintenance, retrofitting, and parts replacement will become a significant revenue stream, providing stability beyond new equipment sales.

Conclusion

In summary, the reciprocating pump market is characterized by steady growth, underpinned by industrial demand, technological innovation, and environmental considerations. While challenges related to cost, competition, and supply chain persist, manufacturers that invest in R&D, regional expansion, and customer-centric services are well-positioned to capitalize on emerging opportunities.