The surge tank market plays a crucial role in modern infrastructure, water treatment systems, energy distribution, and industrial processes. Acting as a buffer to control pressure fluctuations and manage fluid flow within piping systems, surge tanks are indispensable in ensuring operational safety and efficiency. However, despite the growing demand driven by urbanization, infrastructure development, and renewable energy projects, the industry faces several pressing challenges that could potentially hinder its growth trajectory.

One of the foremost challenges in the surge tank market is the volatility in raw material prices. Surge tanks are commonly manufactured using materials such as stainless steel, carbon steel, and composites. These materials are subject to significant fluctuations in global commodity markets due to geopolitical tensions, trade disruptions, and inflation. Manufacturers face increasing difficulty in maintaining cost-efficiency while ensuring compliance with quality standards. As a result, pricing instability affects profit margins and restricts new investments in advanced manufacturing technologies.

In addition, the industry faces rising pressure to meet stringent regulatory standards. From environmental compliance to safety certifications, manufacturers are expected to adhere to both regional and international guidelines. For instance, the implementation of standards such as ASME, ISO, and OSHA regulations demand comprehensive quality testing, documentation, and design precision. Smaller companies often struggle to bear the administrative and financial burden of continuous compliance, while large enterprises must restructure their workflows to accommodate evolving policies. These regulatory hurdles slow down production timelines and increase time-to-market.

Technological advancement is both a driver and a challenge in the surge tank sector. As industries increasingly adopt smart infrastructure, there is mounting pressure to integrate surge tanks with IoT sensors, automation systems, and predictive maintenance tools. However, retrofitting traditional tanks with modern smart systems can be expensive and technically complex. It also requires skilled personnel and significant R&D investment, which not all companies are equipped to handle. The lack of interoperability among devices from different manufacturers further compounds integration issues.

Another critical challenge is the customization demand from end-users across industries. From power plants to wastewater treatment facilities and hydropower stations, each application requires tanks with unique specifications such as size, material composition, and pressure rating. The push for tailor-made solutions strains production capabilities and extends delivery timelines, especially for manufacturers operating on lean production models. Balancing standardization with customization remains a difficult tightrope to walk.

Supply chain disruptions present an ongoing challenge, exacerbated by global crises such as pandemics, natural disasters, and political instability. These events impact the availability of raw materials, delay shipments, and increase logistical costs. For the surge tank market, which often involves heavy and bulky products, timely delivery is essential for project execution. Any delay can result in cost overruns and erode client trust.

Environmental concerns and sustainability pressures have also emerged as critical issues. The industry is now expected to reduce its carbon footprint, use recyclable materials, and adopt cleaner manufacturing practices. This transition demands substantial investment in new machinery and greener technologies. While such changes are necessary for long-term viability, the initial capital expenditure required poses a major barrier, particularly for small and medium-sized enterprises (SMEs).

Workforce challenges, such as the shortage of skilled labor and experienced engineers, further compound the situation. As older professionals retire, there is a noticeable gap in technical knowledge transfer. Training new talent to understand the complexities of pressure systems, safety standards, and precision engineering takes time and resources. Without a robust talent pipeline, manufacturers struggle to maintain quality and innovation standards.

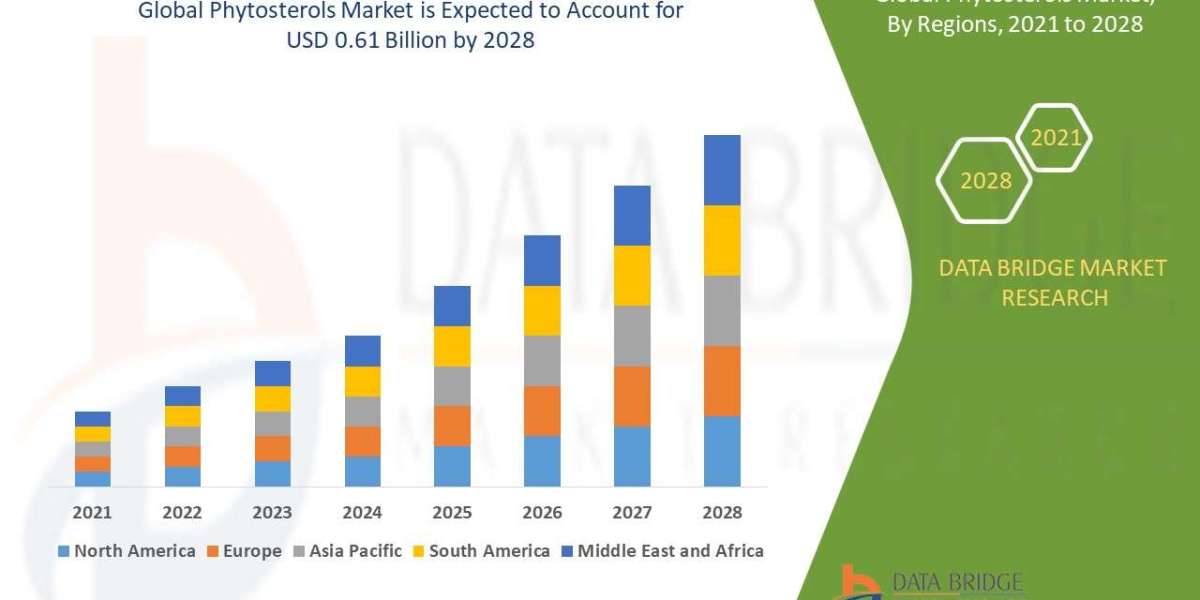

Moreover, regional disparities in infrastructure development present market penetration challenges. While developed economies in North America and Europe have mature infrastructure requiring periodic upgrades, emerging markets in Asia-Pacific, Africa, and Latin America are still in the expansion phase. However, entering these markets involves navigating complex regulatory frameworks, political risk, and variable demand. Local competition and pricing sensitivity also deter international manufacturers from aggressive expansion.

Despite these formidable challenges, the surge tank market holds immense growth potential. Solutions lie in collaborative R&D, government incentives for green manufacturing, digital integration for smarter systems, and workforce development initiatives. Companies that proactively address these challenges will not only survive but thrive in an increasingly complex industrial ecosystem.

In conclusion, while the surge tank market stands on strong technological and infrastructural pillars, it is crucial to recognize and address the multifaceted challenges it faces. Strategic planning, innovation, and adaptability will determine which players lead the next chapter of growth in this vital industry.