In modern metalworking, precision and efficiency are key factors that determine the quality of the final product. One of the most advanced technologies transforming the industry is the hand held metal laser. This powerful tool is widely used for cutting, engraving, and welding metal surfaces with unmatched accuracy. Whether you are a professional fabricator or a DIY enthusiast, a hand held metal laser can significantly enhance your work process.

What is a Hand Held Metal Laser?

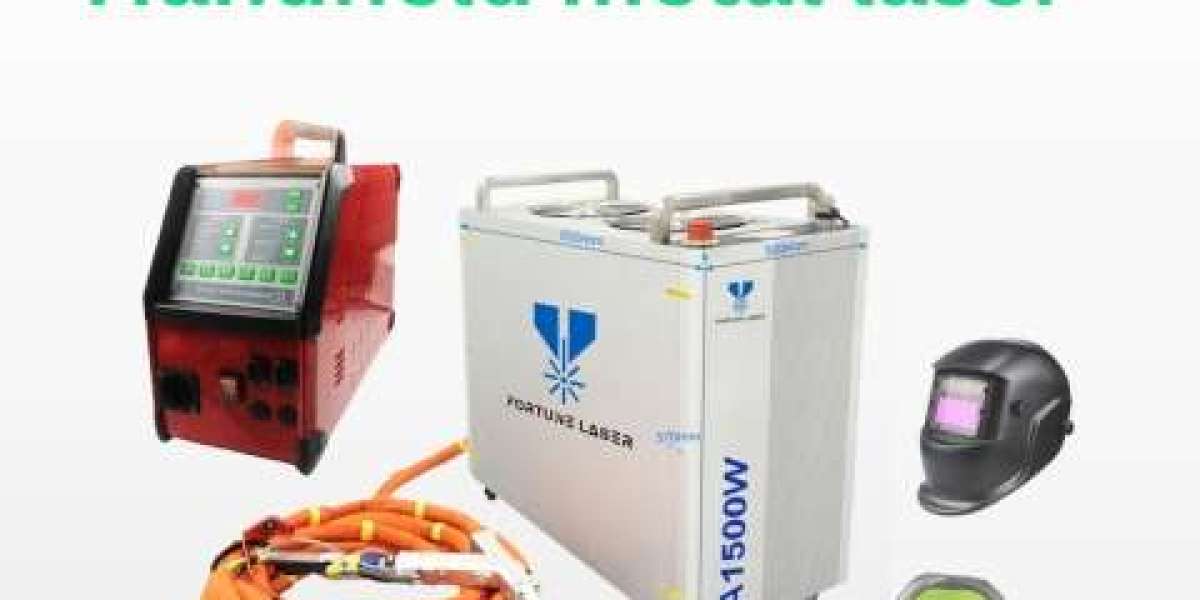

A hand held metal laser is a portable laser device that uses high-intensity laser beams to perform various metal processing tasks. Unlike traditional tools that require heavy machinery and extensive setup, this compact device allows users to cut, weld, or engrave metals with high precision.

These lasers typically operate using fiber laser technology, which is known for its efficiency, durability, and ability to work with different types of metals, including stainless steel, aluminum, copper, and brass.

Key Features and Benefits of a Hand Held Metal Laser

1. High Precision and Accuracy

Hand held metal lasers can achieve clean and precise cuts without causing damage to the surrounding material. This makes them ideal for applications where detailed work is required, such as engraving and fine cutting.

2. Versatility

These lasers are multi-functional, allowing users to cut, weld, and engrave metals using a single device. This versatility makes them a valuable investment for workshops and industrial applications.

3. Portability and Ease of Use

Unlike traditional laser cutting machines, hand held metal lasers are lightweight and portable, making them easy to operate in different locations. Whether you're working in a factory or at a construction site, you can carry and use the device without limitations.

4. Fast and Efficient

Hand held metal lasers operate at high speeds, reducing the time needed to complete metalworking tasks. This efficiency increases productivity, making them ideal for both small-scale and large-scale projects.

5. Cost-Effective Solution

While the initial investment may seem high, a hand held metal laser reduces operational costs in the long run. Since it requires minimal maintenance and consumes less energy, businesses can save money over time.

Applications of Hand Held Metal Lasers

Hand held metal lasers are used in various industries, including:

- Manufacturing: For precise cutting and welding of metal parts.

- Automotive Industry: Used in vehicle repairs and modifications.

- Jewelry Making: Engraving intricate designs on metal surfaces.

- Aerospace Industry: Essential for metal fabrication and repairs.

- Construction: Used in metal welding and customization.

How to Choose the Right Hand Held Metal Laser

When selecting a hand held metal laser, consider the following factors:

- Power Output: Higher wattage provides faster and deeper cutting.

- Material Compatibility: Ensure the laser can work with your preferred metals.

- Cooling System: Good cooling systems prevent overheating and prolong device lifespan.

- Portability: Choose a lightweight and ergonomic design for comfortable handling.

Conclusion

A hand held metal laser is an essential tool for professionals and hobbyists who require precision, efficiency, and versatility in metalworking. Whether you need to cut, engrave, or weld, this device offers unmatched convenience and performance. Investing in the right hand held metal laser can revolutionize your metal fabrication process, helping you achieve superior results with ease.

Would you like to explore the best hand held metal laser options for your needs? Start by researching different models and find the perfect tool for your workshop today!