Introduction

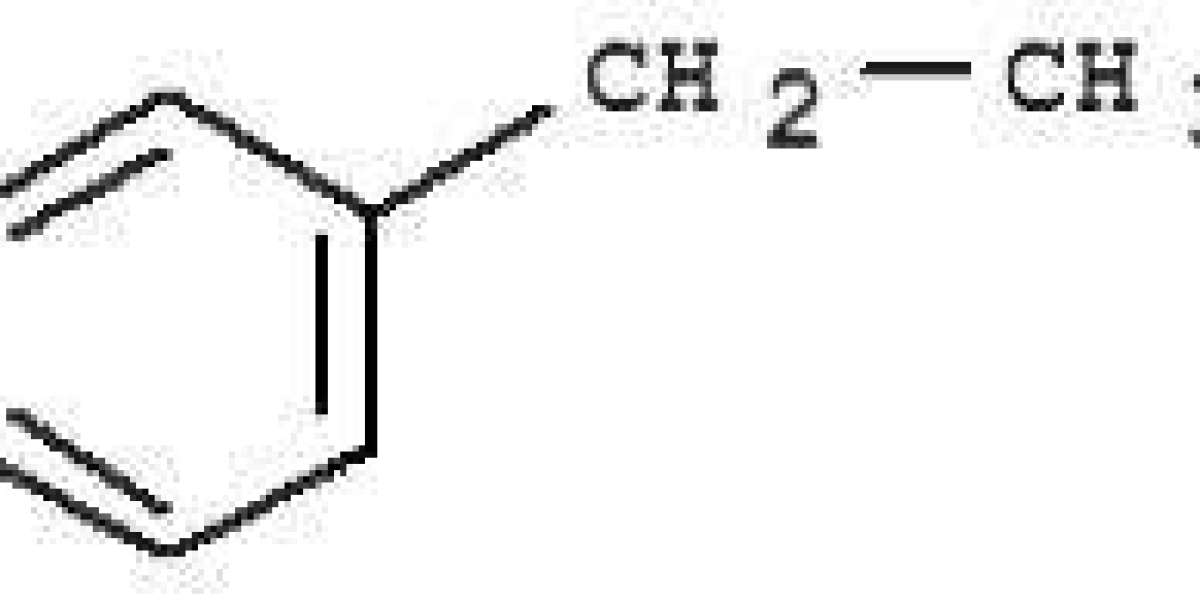

The global ethylbenzene market is undergoing a transformation as industries increasingly prioritize sustainability and environmentally friendly production methods. Traditionally used in styrene manufacturing, ethylbenzene production relies on petrochemical-based processes, raising concerns about its environmental impact. As industries shift toward greener alternatives, opportunities are emerging for sustainable production methods, bio-based feedstocks, and innovative recycling technologies. This article explores the potential for green alternatives in the ethylbenzene market and the factors driving this transition.

1. The Need for Sustainable Alternatives in Ethylbenzene Production

The drive for sustainability in the ethylbenzene market is fueled by several factors:

Environmental Regulations: Governments worldwide are implementing stricter emissions and waste management policies, pushing industries to adopt cleaner production methods.

Carbon Footprint Reduction: The petrochemical industry is a major contributor to greenhouse gas emissions, and companies are seeking ways to reduce their carbon footprint.

Consumer Demand for Eco-Friendly Products: With increasing awareness of environmental issues, consumers prefer sustainable products, influencing businesses to adopt greener raw materials.

Corporate Sustainability Goals: Many multinational corporations have committed to reducing their environmental impact, creating a demand for sustainable chemical alternatives.

2. Emerging Green Alternatives for Ethylbenzene

Several promising alternatives and sustainable practices are gaining traction in the ethylbenzene market:

Bio-Based Ethylbenzene: Research is ongoing to develop ethylbenzene from renewable biomass sources instead of fossil fuels, reducing reliance on crude oil.

Recycling and Circular Economy Initiatives: The adoption of advanced recycling technologies to reuse styrene-based products can lower the demand for virgin ethylbenzene.

Energy-Efficient Production Methods: Innovations in catalytic processes and alternative chemical pathways aim to reduce energy consumption and emissions in ethylbenzene manufacturing.

Carbon Capture and Utilization (CCU) Technologies: Integrating CCU techniques can help reduce CO₂ emissions from petrochemical plants while enhancing sustainability.

3. Market Opportunities and Key Players in Sustainable Ethylbenzene

As industries shift towards greener alternatives, companies are exploring new opportunities in sustainable ethylbenzene production:

Investment in R&D: Leading petrochemical firms are increasing research into bio-based and eco-friendly production processes.

Partnerships with Green Tech Firms: Collaborations between chemical manufacturers and technology companies are fostering innovative solutions for sustainable ethylbenzene production.

Government Incentives and Funding: Regulatory bodies in regions such as the EU and North America are offering subsidies and tax incentives for adopting green production technologies.

Growing Demand in End-Use Industries: Sectors such as packaging, construction, and automotive, which rely on styrene-based materials, are driving demand for sustainable alternatives.

4. Regional Trends in Green Ethylbenzene Adoption

North America:

Strong emphasis on reducing carbon emissions and increasing funding for sustainable chemical manufacturing.

Companies investing in alternative production technologies to meet regulatory requirements.

Europe:

Stringent environmental policies pushing companies to adopt bio-based and energy-efficient ethylbenzene production methods.

Growth in circular economy initiatives, promoting recycling and waste reduction.

Asia-Pacific:

Rapid industrialization and increasing environmental awareness driving demand for sustainable ethylbenzene production.

Government policies encouraging investments in green technologies.

Latin America and Middle East & Africa:

Emerging opportunities for sustainable petrochemical investments as industries look to diversify and modernize operations.

Increased focus on renewable energy and green infrastructure projects supporting eco-friendly chemical production.

5. Future Outlook and Challenges

While the shift towards sustainable ethylbenzene alternatives presents significant opportunities, several challenges must be addressed:

High Initial Investment Costs: Developing bio-based and energy-efficient technologies requires significant funding.

Technological Barriers: Many green alternatives are still in the early stages of research and development.

Market Acceptance and Transition Time: Industries relying on traditional ethylbenzene production may require time to transition to greener alternatives.

Conclusion

The transition to green and sustainable alternatives in the ethylbenzene market is gaining momentum, driven by regulatory pressures, corporate sustainability initiatives, and consumer demand for eco-friendly products. Advances in bio-based production, recycling technologies, and energy-efficient processes present new opportunities for market growth. While challenges remain, the increasing focus on sustainability is expected to reshape the ethylbenzene industry, paving the way for a greener and more environmentally responsible future.