Introduction

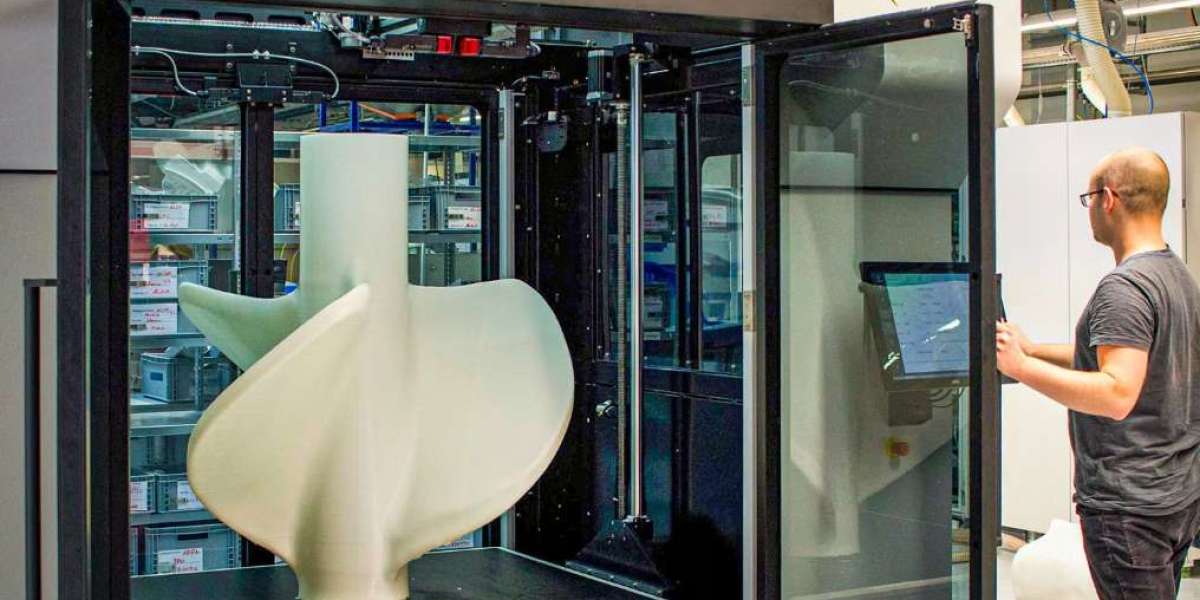

In recent years, 3D printing has revolutionized the manufacturing industry, offering endless possibilities for customization, efficiency, and cost savings. Also known as additive manufacturing, this technology allows businesses and individuals to create complex, high-quality parts with unparalleled precision. From prototyping to mass production, 3D printing is shaping the future of various industries, including aerospace, healthcare, automotive, and consumer goods.

How 3D Printing Works

At its core, 3D printing involves creating three-dimensional objects by layering material, guided by a digital file. Unlike traditional subtractive manufacturing methods, which remove material to form an object, 3D printing adds material layer by layer, minimizing waste and maximizing efficiency. Materials commonly used include plastics, resins, metals, and even ceramics, depending on the specific application.

Advantages of 3D Printing

1. Customization and Design Freedom

One of the biggest advantages of 3D printing is the ability to create fully customized designs without the need for expensive molds or tooling. This makes it ideal for producing unique, intricate components tailored to specific needs.

2. Rapid Prototyping

With 3D printing, businesses can quickly develop prototypes, allowing for faster product iterations and reduced development costs. Engineers and designers can test their ideas in real time, making modifications as needed before moving into full-scale production.

3. Cost-Effective Production

Traditional manufacturing processes often require expensive machinery, labor, and materials. 3D printing significantly reduces production costs by minimizing material waste and automating the manufacturing process.

4. Sustainability and Reduced Waste

Since 3D printing builds objects layer by layer, there is little to no material waste compared to conventional manufacturing methods. Additionally, many 3D printers can utilize biodegradable or recycled materials, further reducing their environmental impact.

Applications of 3D Printing

Healthcare and Medical Innovations

From prosthetics to dental implants, 3D printing is transforming the medical field. Customized implants, surgical guides, and even bioprinting of human tissue are becoming increasingly common, leading to better patient outcomes.

Aerospace and Automotive

In aerospace and automotive industries, 3D printing is used to produce lightweight yet durable parts, enhancing fuel efficiency and performance. Complex geometries that were once impossible to manufacture are now achievable through additive manufacturing.

Consumer Goods and Fashion

Companies are leveraging 3D printing to create personalized products, including footwear, jewelry, and home décor. This allows for on-demand manufacturing, reducing inventory costs and increasing product variety.

Choosing the Right 3D Printing Service

When selecting a 3D printing service, consider factors such as material options, printing technology, resolution, and turnaround time. Working with an experienced provider ensures high-quality prints that meet your specifications and industry standards.

Conclusion

3D printing is revolutionizing the way products are designed and manufactured, offering unmatched customization, efficiency, and sustainability. Whether for prototyping or large-scale production, this technology provides significant advantages across multiple industries. As 3D printing continues to evolve, businesses that embrace this cutting-edge innovation will stay ahead in the competitive manufacturing landscape.