The adsorbent market is experiencing significant expansion, primarily driven by increasing demand across industries such as water treatment, air filtration, and pharmaceuticals. However, this growth trajectory faces various challenges that can affect the overall market potential and adoption rates. Below are key challenges hindering the market growth of adsorbents.

High Production and Raw Material Costs

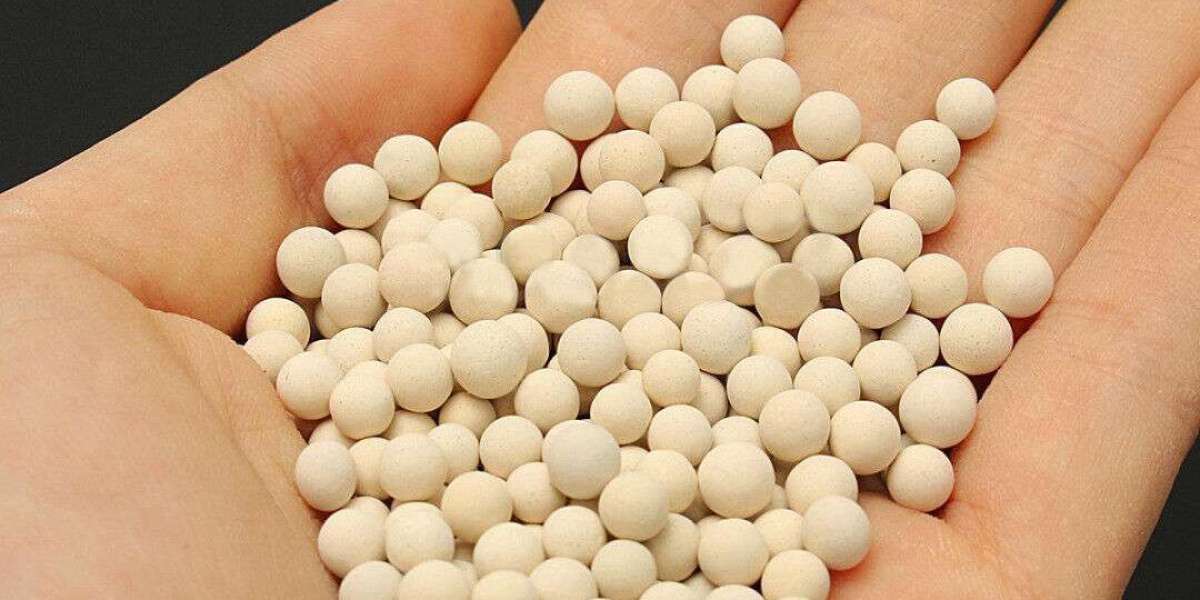

The manufacturing of adsorbents, particularly activated carbon, zeolites, and silica gel, often involves high costs due to the need for specialized raw materials. For instance, silica and zeolites are rare and expensive materials, and obtaining them can strain the supply chain. This results in high production costs for adsorbents, which may prevent smaller companies or industries with low budgets from utilizing these materials. High production costs can also increase the price of end-products, limiting their accessibility in emerging economies.

Supply Chain Issues and Material Shortages

The adsorbent market faces disruptions in its supply chain due to various factors such as limited availability of raw materials and fluctuating prices. Moreover, geographic limitations in sourcing these materials can cause regional supply shortages. For example, activated carbon relies on specific wood or coal sources, and any disruption in their availability can significantly impact the production of adsorbents. This leads to delays in the supply of adsorbents, affecting industries that rely on them for critical applications like water purification and air filtration.

Environmental Impact and Disposal of Spent Adsorbents

Although adsorbents are widely used for environmental protection, such as in water and air purification, the disposal of spent adsorbents can be a challenge. Once used, adsorbents such as activated carbon and zeolites can retain harmful substances, making their disposal a hazardous task. Improper disposal of spent adsorbents can contribute to environmental pollution, negating the positive environmental impact of their initial use. This challenge requires ongoing research into sustainable disposal or recycling methods for spent adsorbents to minimize their ecological footprint.

Regulatory Compliance and Environmental Standards

The adsorbent market is subject to stringent environmental regulations in different regions. These regulations mandate the use of specific types of adsorbents for particular applications, especially in industries such as water treatment, pharmaceuticals, and food processing. While regulations are essential for ensuring quality and safety, they can limit the market's flexibility in terms of product selection and innovation. Moreover, compliance with these standards often requires significant investment in research and development to meet the regulatory criteria, increasing operational costs for manufacturers.

Technological Advancements and Innovation Costs

Technological advancements, such as the development of bio-based adsorbents, molecular sieves, and more efficient forms of activated carbon, can offer greater performance. However, these innovations come at a cost. The research and development efforts required to create new adsorbent materials demand significant investment in technology and infrastructure. While innovation is essential for the evolution of the adsorbent market, the high cost associated with R&D can be a significant barrier, especially for smaller players trying to compete with larger companies that have more resources.

Limited Awareness and Adoption in Emerging Markets

In many developing economies, the use of adsorbents in industrial and environmental applications is still in its infancy. Limited awareness of the benefits of adsorbents for water treatment, air purification, and other critical applications can hinder market adoption. Many industries in emerging markets rely on traditional methods of purification or filtration, which may not be as effective or sustainable as adsorbent-based solutions. The lack of infrastructure and financial resources for adopting advanced adsorbent technologies further limits market growth in these regions.

Competition from Alternative Technologies

The adsorbent market faces increasing competition from alternative technologies that can perform similar functions. For example, reverse osmosis, ion-exchange, and distillation are often used as alternatives to adsorption in water purification, offering different advantages depending on the application. In air filtration, technologies such as electrostatic precipitators and ultraviolet germicidal irradiation are also gaining traction. As these alternatives improve in efficiency and cost-effectiveness, they pose a threat to the growth of the adsorbent market, particularly in niche applications.

Shorter Lifespan of Adsorbents

One of the challenges with certain adsorbents, such as activated carbon, is their relatively short lifespan before they become saturated and need to be replaced. This limits the long-term effectiveness of adsorbents, especially in industries that require continuous filtration or purification. The frequent replacement of spent adsorbents increases operational costs and leads to a higher demand for disposal, contributing to waste management concerns. Research into extending the lifespan of adsorbents or regenerating used adsorbents is critical for mitigating this challenge.

Economic Uncertainty and Impact on Investments

Economic fluctuations and global uncertainties can also negatively impact investments in the adsorbent market. The COVID-19 pandemic, for instance, disrupted supply chains and caused delays in the development and production of adsorbents. Economic downturns or geopolitical tensions can reduce industrial investments in new technologies, including adsorbents, as companies seek to cut costs. As a result, economic instability can hinder the overall growth of the adsorbent market.

Lack of Standardization

The absence of uniform standards for adsorbent materials across different industries and regions creates challenges in quality control and product differentiation. Without clear guidelines for what constitutes an effective or safe adsorbent, manufacturers may face difficulties in meeting consumer expectations. This lack of standardization can lead to inconsistencies in product performance and reliability, reducing consumer confidence and slowing market adoption.