In today’s fast-paced industrial world, efficiency, precision, and sustainability are key factors in manufacturing and maintenance processes. Traditional cleaning methods—such as sandblasting, chemical treatments, and manual scrubbing—often fall short in delivering the desired results. Enter the industrial laser cleaner, a game-changing technology that is transforming how industries handle surface cleaning, rust removal, and coating stripping.

What is an Industrial Laser Cleaner?

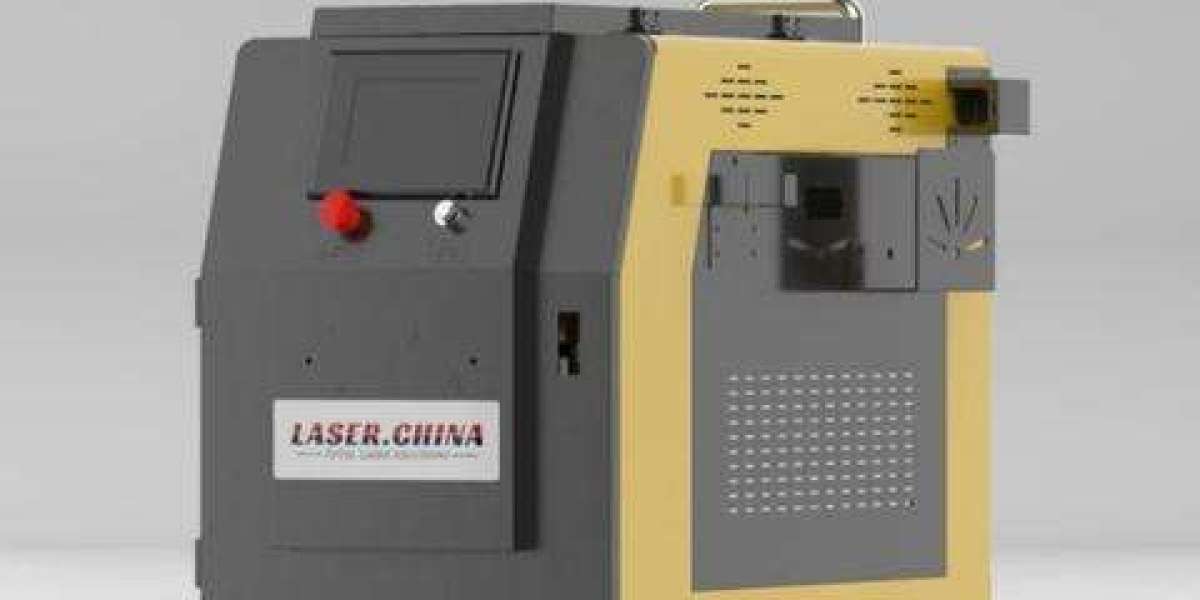

An industrial laser cleaner is a high-tech device that uses concentrated laser beams to remove contaminants, rust, paint, grease, and other unwanted materials from surfaces without causing any damage. Unlike traditional methods, laser cleaning is a non-abrasive, eco-friendly, and highly efficient solution that minimizes waste and operational downtime.

How Does Laser Cleaning Work?

Laser cleaning operates on the principle of laser ablation. When a high-energy laser beam is directed at a surface, it instantly absorbs contaminants like rust or paint. The contaminants evaporate or turn into fine dust particles, leaving behind a clean and pristine surface. This process is precise, ensuring that only unwanted layers are removed without affecting the base material.

Key Advantages of Industrial Laser Cleaning

Non-Destructive & Precise: Unlike traditional methods, laser cleaning ensures that the base material remains intact, making it ideal for delicate and high-value components.

Eco-Friendly Solution: No harmful chemicals, no abrasive materials, and minimal waste—laser cleaning reduces environmental impact and promotes sustainability.

Cost-Effective: Although the initial investment might be higher, laser cleaners significantly cut down on recurring costs associated with chemicals, abrasives, and labor.

Minimal Maintenance & Downtime: Since it’s a contactless method, there’s little to no wear and tear, reducing maintenance costs and increasing efficiency.

Versatile Applications: Industrial laser cleaners can be used across multiple industries, including automotive, aerospace, manufacturing, electronics, and even heritage restoration.

Applications of Industrial Laser Cleaning

Rust & Oxide Removal – Perfect for industries dealing with metal structures, pipelines, and machinery prone to corrosion.

Paint & Coating Stripping – Removes old paint layers efficiently, making it ideal for automotive and aerospace industries.

Grease & Oil Removal – Essential for cleaning mechanical parts without damaging their integrity.

Weld Pre-Treatment & Post-Cleaning – Ensures strong and durable welds by removing contaminants before and after welding.

Surface Preparation – Prepares surfaces for better adhesion before painting or bonding.

Why Invest in an Industrial Laser Cleaner?

As industries strive for greater efficiency, cost savings, and environmental sustainability, investing in an industrial laser cleaner is a forward-thinking move. Whether you are in manufacturing, metal fabrication, aerospace, or automotive, adopting laser cleaning technology can significantly boost your productivity and quality standards.

Upgrade to a Smarter Cleaning Solution – Invest in an Industrial laser cleaner Today!

Final Thoughts

Industrial laser cleaning is the future of surface treatment, offering a faster, cleaner, and safer alternative to traditional methods. With zero chemical waste, low operational costs, and exceptional precision, it’s a must-have for businesses looking to enhance their cleaning processes while reducing their environmental footprint.

Are you ready to transform your cleaning process? Discover the power of an industrial laser cleaner today