In today's industrial landscape, servo motors play a pivotal role in ensuring the seamless operation of automated systems. From manufacturing lines to robotics and CNC machines, servo motors are the driving force behind precise motion control. However, like any mechanical and electrical component, servo motors can experience wear and tear over time. This is where Shawa Technocrafts Private Limited steps in with its top-notch servo motor repairing services, setting a benchmark for quality and reliability.

Understanding the Importance of Servo Motors

Servo motors are advanced electric motors designed for high-performance applications that demand precision, speed, and efficiency. Unlike traditional motors, servo motors are equipped with sensors that provide real-time feedback, enabling precise control of position, velocity, and acceleration. These motors are crucial for industries such as automotive, aerospace, electronics, and packaging, where accuracy and consistency are non-negotiable.

Given their intricate design and critical applications, servo motors require expert maintenance and repair to ensure optimal performance.

Shawa Technocrafts: A Trusted Name in Servo Motor Repairs

Established as a leader in industrial repair solutions, Shawa Technocrafts Private Limited has carved a niche in the realm of servo motor repairs. With years of expertise and a team of skilled technicians, the company has become synonymous with quality, precision, and reliability.

Their comprehensive servo motor repairing services address a wide range of issues, ensuring that your motor operates as efficiently as the day it was installed. Whether dealing with electrical faults, mechanical wear, or sensor malfunctions, Shawa Technocrafts delivers tailored solutions to meet the unique needs of every client.

Common Servo Motor Issues Addressed

Servo motors can encounter several issues due to prolonged usage, environmental factors, or improper handling. Here are some common problems that Shawa Technocrafts effectively resolves:

Electrical Failures

Problems such as short circuits, coil burnouts, and wiring faults are common in servo motors. Shawa Technocrafts employs advanced diagnostic tools to identify and rectify these issues, restoring the motor’s electrical integrity.Encoder or Resolver Malfunctions

Encoders and resolvers are vital for providing feedback to the servo system. Malfunctions in these components can disrupt the motor's precision. The company ensures the repair or replacement of these components for flawless performance.Bearing and Shaft Damage

Continuous operation can lead to wear and tear in bearings and shafts. Shawa Technocrafts offers high-quality replacement and alignment services to ensure smooth mechanical functioning.Excessive Noise or Overheating

Abnormal noise or overheating often indicates internal damage or imbalance. The company's technicians meticulously inspect and address these issues to prevent further complications.

Why Choose Shawa Technocrafts?

Several factors make Shawa Technocrafts a preferred partner for servo motor repairing services:

Expertise and Experience

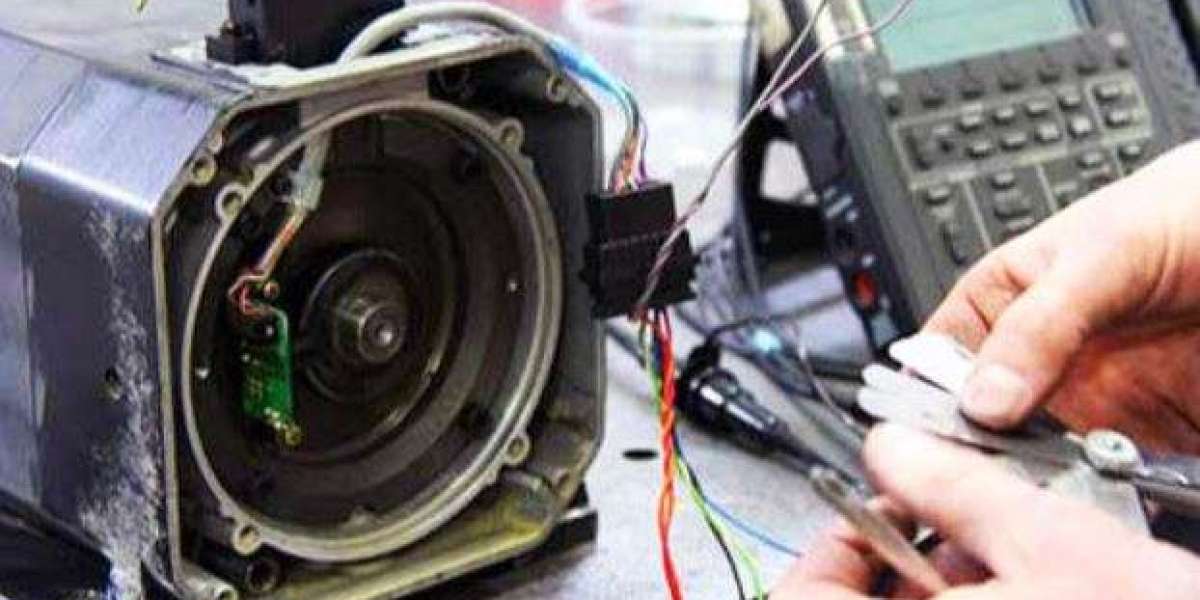

With a team of highly trained professionals, the company brings unparalleled expertise in diagnosing and repairing servo motors. Their experience spans various brands and models, ensuring comprehensive solutions.State-of-the-Art Facilities

Shawa Technocrafts is equipped with cutting-edge diagnostic and testing equipment, enabling accurate fault detection and efficient repairs. Their facilities ensure the highest standards of service quality.Custom Solutions

Understanding that every servo motor is unique, the company tailors its repair services to meet specific client requirements. This personalized approach ensures optimal outcomes for diverse industries.Quick Turnaround Time

Downtime in industrial operations can be costly. Shawa Technocrafts prioritizes efficiency, delivering swift repairs without compromising on quality.Cost-Effectiveness

Replacing a servo motor can be expensive. By opting for Shawa Technocrafts' repair services, clients can save significantly while extending the lifespan of their equipment.

The Repair Process

Shawa Technocrafts follows a systematic approach to ensure reliable repairs:

Initial Assessment

The motor undergoes a thorough inspection to identify visible damage and operational issues.Detailed Diagnosis

Advanced diagnostic tools are used to pinpoint underlying faults in electrical, mechanical, and feedback systems.Repair and Replacement

Faulty components are repaired or replaced using high-quality parts. The motor is reassembled with precision to ensure seamless functioning.Testing and Calibration

The repaired motor undergoes rigorous testing and calibration to meet industry standards and client expectations.Delivery and Installation Support

The repaired motor is returned promptly, with optional installation support to minimize client effort.

Industries Served

Shawa Technocrafts caters to a wide range of industries, including:

- Automotive: Ensuring precision in manufacturing and assembly lines.

- Aerospace: Supporting high-performance systems for critical operations.

- Packaging: Maintaining speed and accuracy in packaging lines.

- Electronics: Enabling precise motion control in electronics manufacturing.

- Robotics: Repairing motors for smooth robotic operations.

Commitment to Quality

At Shawa Technocrafts, quality is not just a promise; it is a practice ingrained in every step of their servo motor repairing services. The company’s adherence to strict quality standards and its commitment to continuous improvement make it a trusted partner for industries nationwide.