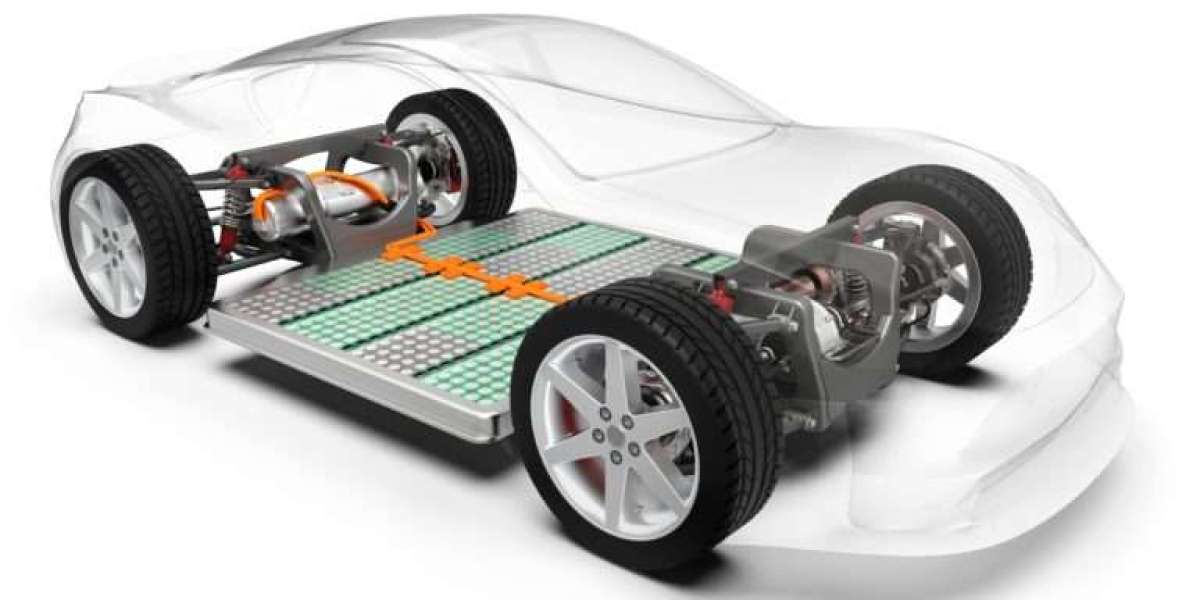

The electric vehicle battery adhesive market is rapidly evolving, driven by the expansion of the electric vehicle industry. As electric vehicles gain traction globally, the demand for high-performance adhesives that can bond battery components and enhance their safety, thermal management, and durability has surged. These adhesives are integral to the assembly and operation of electric vehicle battery packs, influencing key factors such as range, lifespan, and safety. This market’s scope is expanding, with significant advancements in adhesive technology aimed at meeting the diverse needs of modern EV battery designs.

1. Market Size and Growth Projections

The global electric vehicle battery adhesive market is expected to experience substantial growth in the coming years, driven by the rising adoption of electric vehicles, increased production capacity, and the demand for more efficient battery solutions. The market is projected to grow at a compounded annual growth rate (CAGR) of over 20% from 2024 to 2030, reflecting the increasing need for battery adhesives in EV manufacturing. A surge in EV adoption, particularly in the Asia-Pacific region, is expected to be a key driver of this growth.

2. Regional Market Distribution

The electric vehicle battery adhesive market is geographically diverse, with significant growth occurring across several key regions.

- Asia-Pacific holds the largest share, driven by leading EV manufacturers in China, Japan, and South Korea. The region's aggressive push toward electric mobility, coupled with large-scale battery production, is a central factor contributing to the growth of the market.

- North America is experiencing rapid growth due to strong government incentives, increased electric vehicle adoption, and technological advancements.

- Europe has also seen a steady rise in market demand, primarily driven by stringent environmental regulations and the shift towards sustainable transport solutions.

Emerging markets in the Middle East and Latin America are gradually contributing to the market, driven by growing awareness and government support for EV adoption.

3. Types of Adhesives in Market Demand

The types of adhesives used in the electric vehicle battery adhesive market can be categorized based on their chemical composition, including:

- Epoxy adhesives: Known for their superior mechanical strength and thermal resistance, these adhesives are often used in high-performance applications requiring high strength and durability.

- Polyurethane adhesives: These offer flexibility, impact resistance, and excellent bonding properties for battery cells.

- Silicone adhesives: Silicone-based adhesives are gaining popularity for their high-temperature resistance and ability to provide thermal management solutions within battery packs.

- Acrylic adhesives: Known for fast curing and strong bonding capabilities, these adhesives are widely used in cell bonding and structural applications.

Each type of adhesive offers distinct benefits, catering to different needs in battery assembly, thermal management, and sealing.

4. Applications Across the Electric Vehicle Industry

Electric vehicle battery adhesives play a significant role in several key applications within EVs:

- Cell Bonding: Adhesives secure the individual cells within battery packs, maintaining structural integrity during vehicle operation.

- Thermal Management: Many adhesives are designed with excellent thermal conductivity properties, ensuring that EV battery packs remain cool and operate efficiently under heavy usage.

- Sealing and Encapsulation: Adhesives are used for sealing battery packs and protecting sensitive components from external factors such as moisture and dust.

- Electrical Insulation: Certain adhesives provide essential electrical insulation, preventing short circuits and enhancing the overall safety of the battery pack.

5. Emerging Trends and Innovations

The electric vehicle battery adhesive market is seeing continuous innovation, with several emerging trends expected to shape the industry in the coming years:

- Advanced Materials: The development of next-generation adhesive materials, such as those offering enhanced thermal conductivity or electrical insulation, will play a key role in meeting the evolving demands of EV manufacturers.

- Eco-friendly Adhesives: As the automotive industry increasingly emphasizes sustainability, there is a growing shift toward the development of environmentally friendly adhesives. Biodegradable and low-VOC adhesives are expected to gain traction.

- Automation and Smart Manufacturing: The growing use of automated adhesive application methods and smart manufacturing techniques in battery assembly processes is expected to improve efficiency and reduce production costs.

These innovations reflect a push towards improving battery performance, efficiency, and safety while reducing the environmental impact of production processes.

6. Competitive Landscape

The electric vehicle battery adhesive market is competitive, with numerous players focusing on developing specialized adhesive solutions for battery applications. Companies like 3M, Henkel, Sika AG, H.B. Fuller, and Dow are key contributors to market development.

- Henkel has developed a range of high-performance adhesives used in the automotive sector, focusing on adhesives that can withstand high temperatures and offer excellent electrical insulation properties.

- 3M offers innovative solutions with adhesives that ensure superior bonding strength and reliability in EV battery packs.

In addition, new entrants and start-ups are developing eco-friendly and specialized adhesives designed for next-generation batteries, ensuring a dynamic market environment.

7. Challenges and Barriers

Despite the rapid growth of the market, several challenges need to be addressed:

- High Adhesive Costs: Advanced adhesives required for EV batteries are often expensive, which can drive up the overall cost of manufacturing.

- Material Compatibility: Adhesive formulations must be compatible with various materials used in battery packs, which can be a technical challenge.

- Regulatory Compliance: The need for adhesives to meet stringent industry regulations in terms of safety, performance, and environmental standards can add complexity to the development process.

8. Future Opportunities and Outlook

The future outlook for the electric vehicle battery adhesive market is positive, with opportunities arising from increased demand for higher-capacity batteries, advancements in solid-state battery technology, and a stronger push toward sustainability. Manufacturers are likely to focus on developing cost-effective, high-performance, and eco-friendly adhesive solutions to meet these evolving needs. Additionally, collaboration between adhesive suppliers, battery manufacturers, and automakers will play a key role in driving market growth.