Among the many materials available, wood filament has gained popularity for its aesthetic appeal and environmentally friendly properties. Combining PLA (polylactic acid) with wood particles, wood filament offers a unique opportunity to create beautiful prints while aligning with sustainable practices. This article explores the environmental performance of wood filament and why it is a promising option for eco-conscious makers and manufacturers.

Renewable and Biodegradable Composition

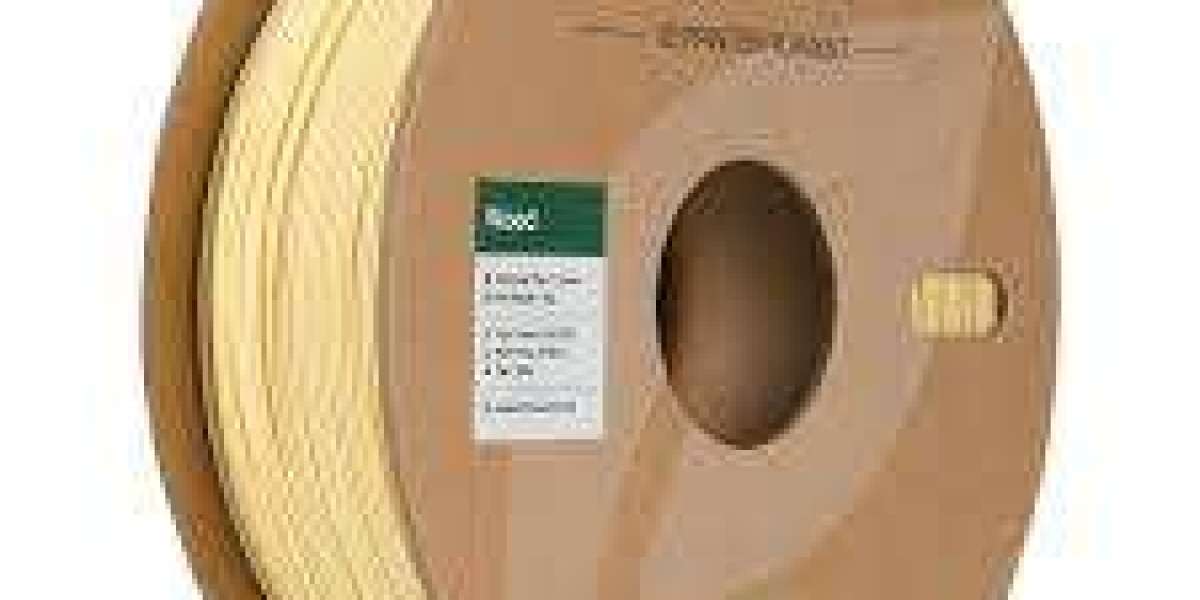

Wood filament primarily consists of a blend of PLA, a biodegradable plastic derived from renewable resources such as corn starch or sugarcane, and finely ground wood particles. This combination creates a composite material that is significantly more environmentally friendly than petroleum-based filaments like ABS or PETG. The use of renewable biomass sources for both components helps reduce dependence on fossil fuels and lowers the carbon footprint of production.

PLA’s inherent biodegradability under industrial composting conditions means that end-of-life disposal of wood filament prints has a reduced environmental impact. Unlike traditional plastics that can persist in the environment for centuries, PLA-based wood filament can break down more naturally when disposed of correctly. This characteristic makes wood filament an attractive option for projects that emphasize eco-friendly design.

Energy-Efficient Production and Printing

Compared to conventional manufacturing processes, 3D printing using wood filament is inherently more energy-efficient. Additive manufacturing builds objects layer by layer, minimizing material waste and reducing the need for extensive post-processing. The incorporation of wood particles into the filament further enhances its environmental performance by providing a way to reuse byproducts or waste from the wood industry.

Moreover, many wood filaments are formulated to print at lower temperatures than other composite materials, which reduces the energy consumption of 3D printers during operation. While the exact energy savings will vary depending on the specific printer and settings, using wood filament often results in a more sustainable overall production cycle.

Aesthetic Appeal and Reduced Need for Post-Processing

Wood filament produces prints with a natural, wood-like texture and appearance, making it a preferred choice for decorative items, artistic sculptures, and furniture components. Unlike other 3D printing materials that may require extensive finishing work (such as sanding, painting, or chemical treatments), wood filament prints often require minimal post-processing. The distinctive wood grain effect can be enhanced by light sanding, staining, or varnishing, reducing the need for additional coatings or non-biodegradable finishes.

By minimizing post-processing, wood filament helps reduce the consumption of chemicals and energy, further enhancing its environmentally friendly profile.

Challenges and Opportunities

Despite its positive environmental attributes, wood filament does have some challenges. For instance, it is more hygroscopic (moisture-absorbing) than standard PLA, meaning it needs proper storage to avoid degradation. Additionally, achieving consistent print quality can be more challenging due to the unique blend of wood particles, which may impact nozzle wear and print stability. Manufacturers and users must address these challenges to maximize the sustainability of wood filament.

To further enhance the environmental performance of wood filament, continuous innovation and development are necessary. This includes optimizing wood particle sourcing from sustainably managed forests, improving filament formulations for better print consistency, and creating effective recycling programs for PLA and wood-based 3D printed objects.

Encouraging Circular Economy Practices

One way to improve the environmental impact of wood filament is to embrace circular economy principles. By focusing on reducing, reusing, and recycling, makers can minimize waste and extend the life cycle of wood filament products. Reusing failed prints or scrap material through grinding and re-extrusion can reduce the demand for virgin filament and lessen the environmental impact of 3D printing operations.

Conclusion

The environmental performance of wood filament offers a compelling reason for makers and manufacturers to incorporate it into their 3D printing projects. With a blend of renewable PLA and natural wood particles, it provides an eco-friendly alternative that minimizes carbon emissions, reduces plastic waste, and offers energy-efficient production. While there are challenges to address, the sustainable potential of wood filament makes it an exciting material for environmentally conscious innovation in the 3D printing industry. By prioritizing sustainable practices and continuous improvement, wood filament can pave the way for greener, more responsible 3D printing applications.