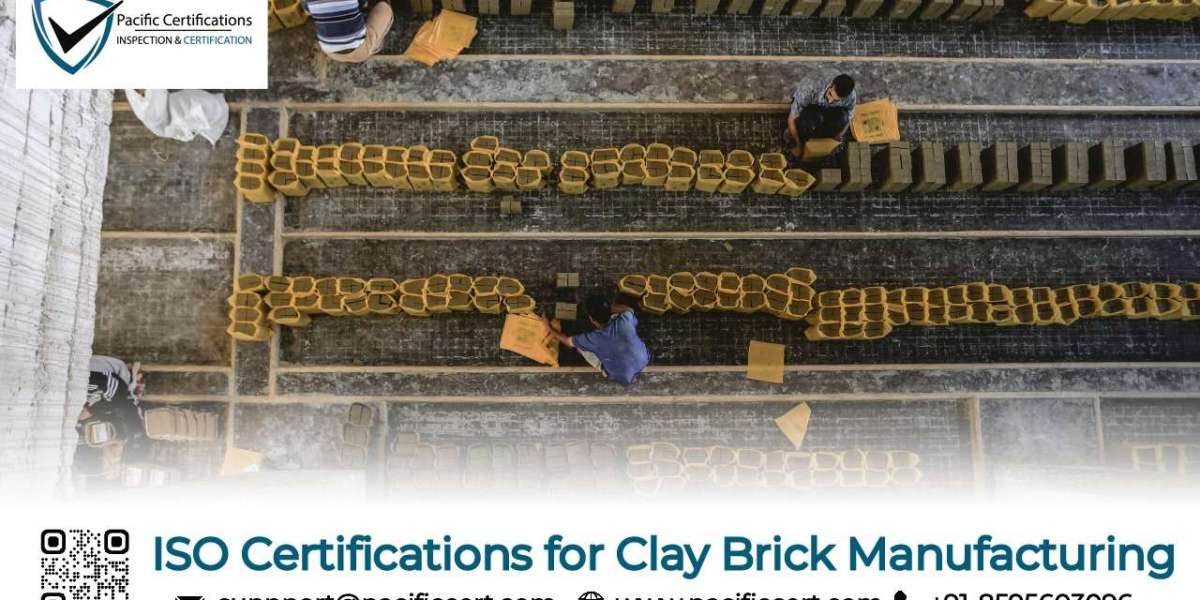

In the world of clay brick manufacturing, consistency and quality are paramount. Every brick must meet exacting standards to ensure structural integrity and durability. But beyond crafting high-quality products, clay brick manufacturers are also responsible for addressing environmental, health, and safety concerns.

This is where ISO certifications come in, they provide a structured framework that enhances quality, ensures sustainability, and fosters safer working conditions. Let’s dive deeper into the world of ISO certifications and explore how they benefit clay brick manufacturing.

What is ISO Certification?

ISO, or the International Organization for Standardization, creates standards that ensure quality, safety, and efficiency across industries. ISO certifications verify that a company adheres to globally recognized standards, making it a valuable asset in manufacturing. For clay brick manufacturers, ISO certifications represent a commitment to excellence, environmental responsibility, and safety.

ISO Standards Applicable to Clay Brick Manufacturing

While numerous ISO standards exist, four stand out as particularly relevant for clay brick manufacturing:

- ISO 9001: Quality Management System (QMS) — Ensures products meet customer and regulatory requirements consistently.

- ISO 14001: Environmental Management System (EMS) — Helps companies reduce their environmental footprint.

- ISO 45001: Occupational Health and Safety — Focuses on reducing workplace risks.

- ISO 50001: Energy Management — Encourages energy efficiency.

Click here to find out more applicable standards to your industry

These standards align clay brick manufacturing with global practices, promoting quality, sustainability, and safety.

Email us at: [email protected], and we’ll guide you through the certification process.

The Significance of ISO 9001 for Quality Management in Brick Manufacturing

Quality management is at the heart of ISO 9001. It ensures that clay bricks are manufactured to precise standards, leading to products that meet and exceed customer expectations. For brick manufacturers, ISO 9001 implementation brings about a culture of continuous improvement, streamlined processes, and defect reduction. This standard provides a solid foundation for quality assurance and customer satisfaction.

The Role of ISO 14001 in Environmental Sustainability

Clay brick manufacturing is energy-intensive and involves the extraction of natural resources. ISO 14001 helps businesses reduce their environmental footprint by managing resources responsibly, reducing waste, and adhering to environmental regulations. Implementing ISO 14001 positions a company as an environmentally conscious leader, appealing to eco-aware customers.

Enhancing Workplace Safety with ISO 45001

Brick manufacturing involves high temperatures, heavy machinery, and exposure to dust, posing various health and safety risks. ISO 45001 focuses on creating a safer work environment by identifying hazards, implementing controls, and promoting safety practices. For brick manufacturers, ISO 45001 is a game-changer in fostering a safety-first workplace culture.

The Importance of Energy Efficiency in Brick Manufacturing

Energy efficiency is critical in an energy-intensive industry like brick manufacturing. ISO 50001 provides a framework for energy management, helping manufacturers reduce consumption and costs. It focuses on monitoring, optimizing, and continuously improving energy usage, which aligns well with sustainability goals and lowers operational costs.

Your ISO certification is a call away: Dial +91–8595603096, and Pacific Certifications will assist you every step of the way.

Benefits of ISO Certifications for Clay Brick Manufacturers

- Product Quality: ISO standards enhance the consistency and quality of bricks, resulting in superior products.

- Customer Trust: Certification boosts brand reputation, building trust with customers who value quality.

- Efficiency and Reduced Costs: ISO implementation often leads to streamlined operations, reducing waste and operational costs.

- Environmental Compliance and Responsibility: With standards like ISO 14001 and ISO 50001, manufacturers are more environmentally responsible.

- Safer Workplaces: ISO 45001 promotes a safe work environment, reducing accident rates and improving morale.

ISO Certification Requirements for Brick Manufacturers

To achieve ISO certification, manufacturers must meet specific requirements related to documentation, process control, risk assessment, and continuous improvement. Key requirements include:

- Documented quality and safety policies

- Standard operating procedures (SOPs)

- Regular training programs

- Commitment to continual improvement

ISO Certification Process for Clay Brick Manufacturing

The certification process begins with a gap analysis to identify areas needing improvement. Then comes the documentation, followed by the implementation of new processes and standards. Finally, an audit assesses compliance, with successful companies earning certification.

Implementing ISO Standards: Challenges and Solutions

Implementing ISO standards can present challenges such as employee resistance, high initial costs, and the need for extensive documentation. However, these challenges are mitigated by a structured approach, training, and support from management. Focusing on long-term benefits can make the transition smoother.

Impact of ISO Certification on Business Growth

For clay brick manufacturers, ISO certification can open doors to new markets and customers, especially in regions where quality and safety standards are highly valued. Certification often attracts more clients, increases competitiveness, and leads to sustained growth.

Cost Considerations of ISO Certification for Brick Manufacturers

Certification involves costs related to audits, documentation, and training. However, the return on investment (ROI) is significant over time, as certification drives efficiency, reduces wastage, and enhances reputation. Many companies find that these long-term benefits outweigh the initial investment.

Preparing for an ISO Audit in Clay Brick Manufacturing

Preparing for an audit involves ensuring all processes align with ISO standards. Key preparation steps include reviewing documentation, conducting internal audits, and ensuring that all employees understand the importance of the certification standards.