Why is Online Motor Monitoring Profitable?

With factory automation becoming a common trend in the contemporary times, many of the tasks, earlier done manually are done with the help of machines, propelled by motors. Every motor is designed in a way to provide efficient results to say the least. But having said that, the monitoring of the motors is important for ensuring that is there everything fine with the motor, or there is a need of some sort of overhauling or repair.

Not much time has passed when all the motor monitoring was static, but now the times have changed with online motor monitoring coming to the forth, it can really speed up the predictive maintenance programs.

Now, let us see, what all online motor maintenance can help you achieve.

Help in Reducing Downtime

With online motor monitoring, the foremost thing that you can achieve, is cutting on the downtime. When there is something wrong with the motor, and it is not functioning properly, it will increase the downtime of the machines This can lag all the processes, and there can be a lull on the production lines.

With online motor monitoring, it is possible for the engineers to keep an eye on the working of the motor, by not being physically present on-site. This ensures fast diagnostics, and effective maintenance, therefore preventing downtime.

Proactive and Not Reactive Motor Maintenance

With online motor monitoring, there is always a proactive maintenance, rather than reactive. As opposed to the conventional motor monitoring, online motor monitoring can also come good for the predication of future system failures before they take place in reality.

This enables a proactive method to the maintenance of motors. Alerts sent through emails and SMS allow the engineers to take charge of the motor, inspect, and fix any issue, before the problem starts to take monstrous proportions.

With process surveillance and equipment automation, production efficiency can be significantly improved. Data collation and interpretation can prove to be a tedious task that is error-prone even with the most dedicated of workers.

Tasks can be Done More Efficiently

Online motor monitoring systems can effortlessly collect all the data, regarding the previous maintenance schedules, that would otherwise require much human staff and intervention. Consequently, the motor will work just fine and with increased efficiency, and that too for a long time.

Moreover, the engineers and workers, who would otherwise be needed for monitoring and maintaining the motor and collecting all the necessary data can be put to some other production aspects.

Getting Motor Performance Insights

Online motor monitoring lets operators gain valuable insight into how efficient, the motor is performing. Data collected by the online monitoring software can be graphically represented showing the performance of a motor over a given time.

Consequently, representations of the performance of the motor can be employed for taking a call on the life of the motor, if it is out of the prime and needs to be replaced or there are some more good years left.

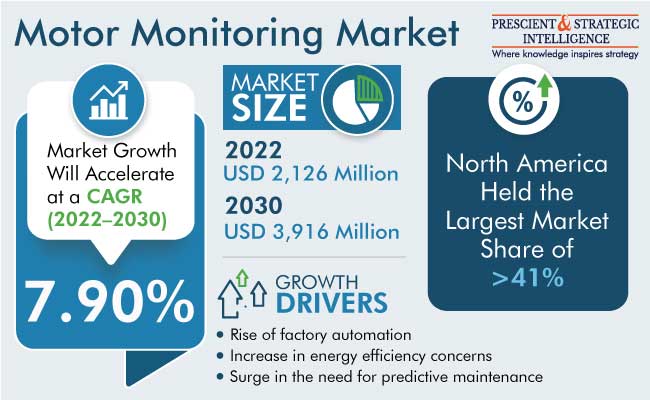

It is because of the increasing factory automation, the need for motor monitoring will also rise, and reach a value of USD 3,916 million, by the end of this decade.

Read More: https://www.psmarketresearch.c....om/market-analysis/m