@african

Forged Steel Gate Valve Supplier in Libya

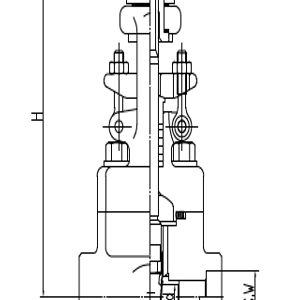

African valve is a leading Forged Steel Gate valve supplier in Libya .A forged steel gate valve is a type of valve that is commonly used in industrial applications to control the flow of fluids or gasses. It is constructed using forged steel, which undergoes a manufacturing process where the metal is shaped and formed under high pressure and heat. This forging process enhances the strength and durability of the valve, making it suitable for handling high-pressure and high-temperature applications.

The gate valve gets its name from the gate-like disc or wedge-shaped closure element that moves up and down within the valve body to control the flow. When the valve is fully open, the gate is lifted, allowing unrestricted flow, and when it is fully closed, the gate creates a tight seal, preventing the flow of fluid or gas.African valve is the best Forged steel Gate valve supplier in Libya. The forged steel construction of the valve provides excellent resistance to corrosion, wear, and high-pressure conditions, making it a reliable choice for demanding environments such as oil and gas, power plants, and chemical processing plants. The design of forged steel gate valves allows for efficient and precise control of flow, making them well-suited for applications that require reliable isolation and on-off functionality.

Parts:

Body

Bonnet

Gate

Stem

Seat:

Gland and Packing

Bolts and Nuts

Handwheel or Actuator

Types:

Pressure Seal Gate Valve

Welded Bonnet Gate Valve

Rising Stem Gate Valve

Non-rising Stem Gate Valve

Flexible Wedge Gate Valve

Advantages:

Durability: Forged steel gate valves are known for their exceptional strength and durability. The forging process enhances the structural integrity of the valve, making it resistant to wear, corrosion, and high-pressure conditions.

High Pressure and Temperature Capability: These valves are designed to handle high-pressure and high-temperature applications, making them suitable for industries such as oil and gas, petrochemicals, power generation, and refining.

Tight Shut-Off: Gate valves provide a tight shut-off by using a gate (disk) that completely blocks or allows the flow of fluid. This feature makes them ideal for applications that require precise flow control and isolation.

Low Pressure Drop: The design of gate valves minimizes pressure drop across the valve, resulting in efficient fluid flow and reduced energy consumption.

Versatility: Forged steel gate valves can handle a wide range of fluids, including corrosive and abrasive media. They are compatible with different piping systems and can be used in both on-off and throttling applications.

Applications :

Oil and Gas Industry: Forged steel gate valves are commonly used in the oil and gas industry, particularly in upstream and downstream operations such as exploration, production, refining, and transportation. They can handle the high-pressure and high-temperature conditions encountered in these applications.

Petrochemical Industry: Gate valves find extensive use in the petrochemical industry for controlling the flow of various chemicals, gases, and liquids. They are suitable for processes involving corrosive media and harsh operating conditions.

Power Generation: Power plants, including thermal power plants and nuclear power plants, utilize forged steel gate valves for controlling steam, water, and other fluids in the system. Gate valves are critical components in boiler feedwater systems, turbine bypass systems, and cooling water systems.

Refining Industry: Gate valves are used in refining processes for controlling the flow of petroleum products, chemicals, and gases. They are commonly found in applications such as crude oil distillation, fluid catalytic cracking, and hydrotreating.

Industrial Applications: Forged steel gate valves are employed in various industrial processes, including water treatment plants, mining operations, pulp and paper mills, and chemical manufacturing facilities. They provide reliable and efficient flow control in these diverse applications.

Description

Sizes– 1/2″ to 2″

Class: 150 to 2500, PN25 to PN450

Material: A105, F11, F22, F51, LF2, F304, F304L, F316, F316, F91

End Connections: Buttweld, Socket weld, Flanged, Threaded

Visit our website to know more:

https://www.africanvalve.com/p....roduct-category/forg