The basics of electromagnetic induction heaters

Electromagnetic induction heater is a kind of heating equipment using electromagnetic induction principle, which is widely used in industrial heating, metal treatment, medical equipment disinfection, food processing and other fields. The following is an introduction to the basic knowledge of electromagnetic induction heaters:

1. working principle

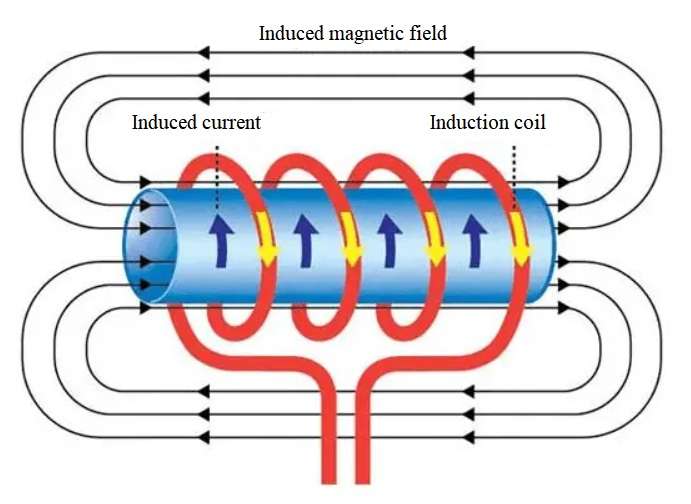

The working principle of electromagnetic induction heaters is based on Faraday's law of electromagnetic induction. When an alternating current flows through the coil of the heater, a changing magnetic field is created around the coil. When a conductive material, such as a metal, is placed in this changing magnetic field, the change in the magnetic field creates eddy currents (i.e. closed current loops) inside the material. These eddies cause a heating effect on the electrical resistance of the metal, which heats up the metal.

2. Components

Electromagnetic induction heater is mainly composed of several parts:

1). Coil: usually made of copper or aluminum, used to generate a strong magnetic field.

2). Power supply: provides alternating current, and its frequency and intensity can be adjusted according to needs to adapt to different heating requirements.

3) Cooling system: Because coils and other components generate heat during heating, a cooling system (such as water cooling or air cooling) is needed to maintain the normal operation of the equipment.

4) Control system: used to adjust the power output, control the heating temperature and time, etc., to ensure the accuracy and repeatability of the heating process.

3: Advantage

1) High efficiency: electromagnetic induction heating efficiency is high, can quickly convert energy into heat.

2) Energy saving: Compared with traditional heating methods, electromagnetic induction heating can reduce energy consumption and operating costs.

3) Environmental protection: no need to burn fossil fuels, no emissions, more environmentally friendly.

4) Precise control: the temperature and position of the heating can be accurately controlled to improve product quality and consistency.

5) Safety: Because there is no open flame, it is safer to use, especially suitable for flammable and explosive environment.