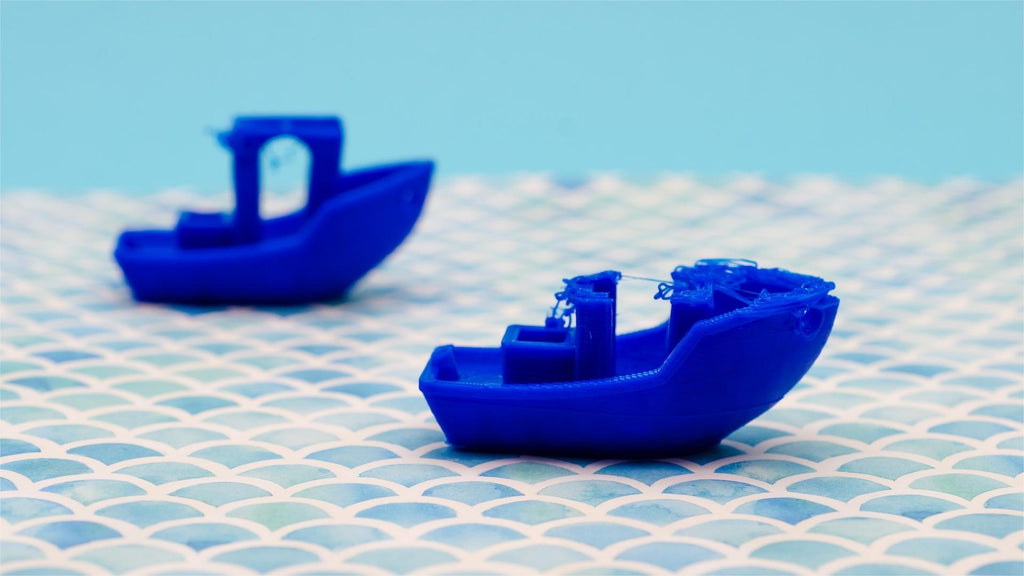

Understanding 3D printing troubleshooting is essential for both beginners and experienced users. This guide aims to provide insights into common issues encountered during the 3D printing process and offers practical solutions to enhance your printing experience.

Understanding 3D Printing Troubleshooting: Common Issues

When delving into the world of 3D printing, you may encounter various challenges. Some of the most frequent problems include:

- Filament Jamming: This occurs when the filament gets stuck in the extruder, preventing proper flow.

- Layer Separation: Layers may not adhere properly, leading to weak prints.

- Stringing: This issue manifests as thin strands of filament connecting different parts of the print.

- Warping: The edges of the print may lift off the build plate, causing distortion.

Understanding 3D Printing Troubleshooting: Causes and Solutions

To effectively address these issues, it is crucial to understand their underlying causes. Here are some common problems along with their potential solutions:

- Filament Jamming:

- Check the filament path for obstructions.

- Ensure the extruder temperature is set correctly for the filament type.

- Layer Separation:

- Increase the print temperature to improve layer adhesion.

- Adjust the print speed to allow more time for layers to bond.

- Stringing:

- Reduce the temperature of the nozzle.

- Enable retraction settings in your slicing software.

- Warping:

- Use a heated bed to maintain consistent temperatures.

- Apply adhesive solutions like glue stick or hairspray on the build plate.

Understanding 3D Printing Troubleshooting: Best Practices

To minimize the occurrence of these issues, consider implementing the following best practices:

- Regularly calibrate your 3D printer to ensure optimal performance.

- Use high-quality filament to reduce the likelihood of jams and defects.

- Maintain a clean build plate to enhance adhesion.

For a more comprehensive understanding of 3D printing troubleshooting, you can explore additional resources, such as the 3D Printing Troubleshooting Guide.

Conclusion: Mastering 3D Printing Troubleshooting

In conclusion, understanding 3d printing troubleshooting is vital for achieving successful prints. By recognizing common issues and implementing effective solutions, you can significantly enhance your 3D printing experience. Remember, every challenge presents an opportunity to learn and improve your skills in this fascinating field.