In the realm of modern manufacturing, the precision and quality of injection moulds play a pivotal role in shaping the products we use daily. Two key areas where this craftsmanship is prominently displayed are in the creation of Home Appliance Plastic Injection Mould and Plastic Crates Injection Moulds Manufacturers.

Home appliance plastic injection moulds are essential components in the production of a wide range of household items. From sleek and efficient kitchen appliances to cutting-edge electronic devices, these moulds form the foundation for the intricate designs that define contemporary living. The process begins with meticulous design and engineering, ensuring that every contour and detail is captured with precision. Skilled artisans then bring these digital blueprints to life, crafting moulds that will be the catalyst for mass production.

One of the critical factors in home appliance mould manufacturing is material selection. Engineers carefully choose plastics that not only meet the product's functional requirements but also adhere to sustainability goals. The goal is to strike a balance between durability, aesthetic appeal, and environmental consciousness. The injection moulding process itself involves the high-pressure injection of molten plastic into a carefully crafted mould, a process that demands exactitude to produce flawless end products.

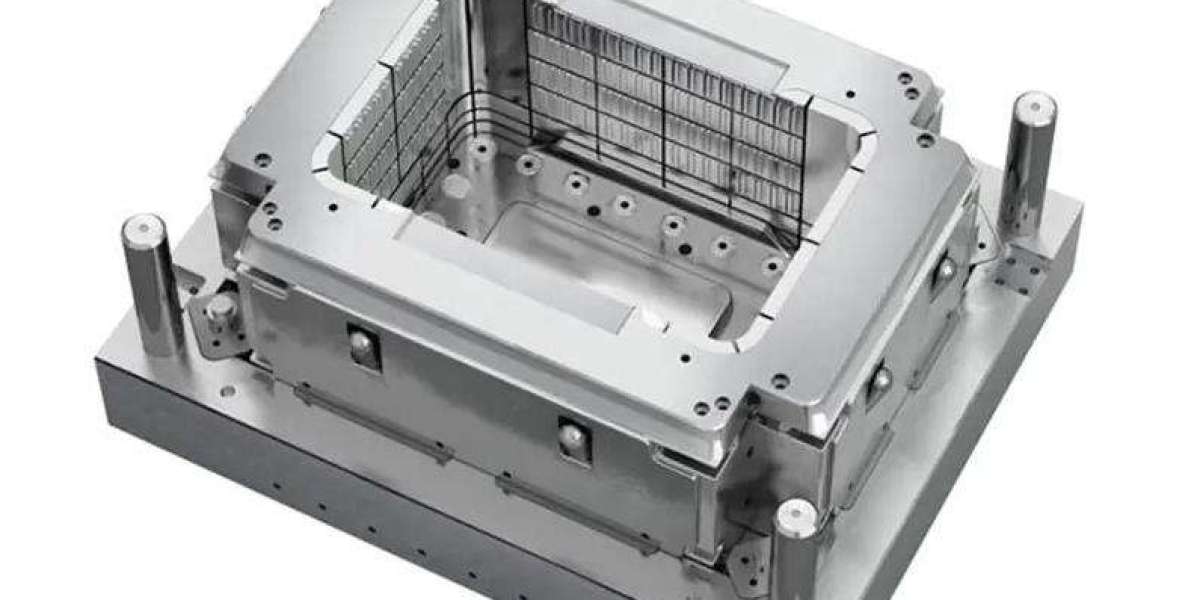

On the other side of the spectrum, plastic crates injection moulds are indispensable in the logistics and storage industries. These unassuming yet robust moulds are the unsung heroes behind the transportation and organization of goods worldwide. Plastic crates are favored for their durability, lightweight nature, and versatility. The injection moulds responsible for their creation undergo a rigorous manufacturing process to ensure they can withstand the demands of various industries.

The design of plastic crate moulds requires an understanding of the diverse needs they serve. From the agricultural sector to retail and beyond, these moulds must accommodate varying sizes, weights, and shapes of products. The injection moulding process for plastic crates is engineered to produce consistent results, meeting the stringent requirements of industries reliant on efficient and reliable storage solutions.

Both home appliance and plastic crates injection moulds share a common thread in their manufacturing processes – the pursuit of excellence. Skilled craftsmen utilize advanced technology and their expertise to create moulds that stand the test of time. Quality control measures are implemented at every stage, ensuring that each mould meets the exacting standards set by the industry.

Furthermore, the evolution of injection moulding technology continues to shape the landscape of manufacturing. Innovations such as multi-cavity moulds, hot runner systems, and advanced cooling techniques contribute to increased efficiency and reduced waste in the production process. Manufacturers are continually pushing the boundaries of what is possible, embracing technological advancements to stay at the forefront of the industry.

In conclusion, the craftsmanship involved in home appliance and plastic crates injection mould manufacturing is a testament to the dedication of skilled professionals in the field. As we interact with the products of modern living and witness the seamless logistics of global trade, it's important to recognize the intricate process behind their creation. The future holds the promise of further advancements, ensuring that injection moulding remains a cornerstone of contemporary manufacturing.