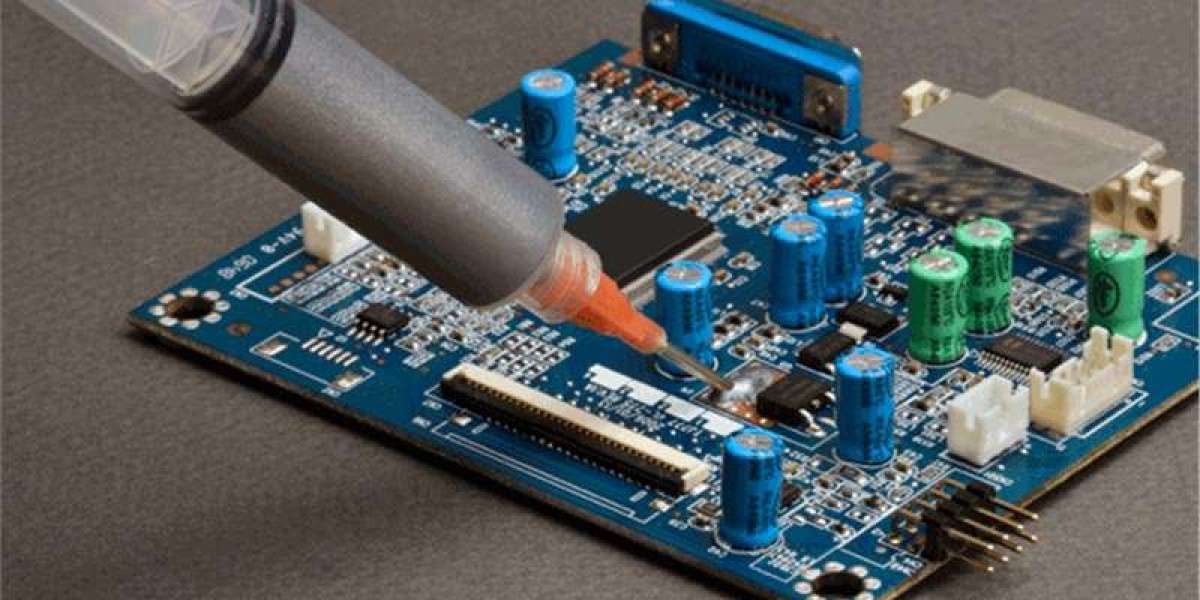

The electronics adhesives market faces several growth challenges as it evolves with the increasing demand for miniaturization, performance improvements, and sustainability. This sector, integral to electronic devices, is witnessing significant innovations and new applications. However, the market growth is hindered by various hurdles that impact its potential to expand. Some of the prominent challenges faced by the electronics adhesives market are outlined below.

Rising Raw Material Costs

- The prices of raw materials, including polymers, resins, and other chemicals, are increasing due to supply chain disruptions and geopolitical tensions.

- The volatility in the cost of these materials makes it difficult for manufacturers to set competitive prices while maintaining profitability.

- Adhesive manufacturers face challenges in passing on the costs to customers, leading to margin pressures.

Stringent Environmental Regulations

- Regulatory agencies worldwide are implementing stricter environmental guidelines and standards for the manufacturing and disposal of adhesives.

- Electronics adhesives must comply with RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives.

- Adapting products to meet these regulations requires additional research, development, and costs, slowing down market adoption.

Technological Complexity

- The increasing complexity of electronic products, such as flexible displays, 5G technology, and electric vehicles, requires adhesives that offer advanced properties like conductivity and high-temperature resistance.

- The challenge lies in developing adhesives that not only meet the technological demands but also maintain their functionality over time under harsh conditions.

- The ongoing demand for customized adhesive solutions complicates the production process and increases costs.

Supply Chain Disruptions

- The global electronics adhesives market is dependent on a complex supply chain, which is vulnerable to disruptions caused by natural disasters, pandemics, and trade restrictions.

- These disruptions can lead to delays in production and shipment, creating challenges for companies trying to meet growing demand.

- Ensuring a reliable and stable supply chain is a significant hurdle for businesses in this industry.

Competition from Alternative Technologies

- Traditional adhesives face increasing competition from alternative bonding technologies, such as laser welding, ultrasonic bonding, and soldering.

- These technologies may offer faster processing times, higher bonding strength, and cost-effectiveness, leading some manufacturers to consider alternatives to adhesive solutions.

- Overcoming the competition from these alternatives requires continuous innovation and significant investments in R&D.

Shortage of Skilled Labor

- The electronics adhesives industry requires a skilled workforce capable of developing new adhesive formulations and applying them effectively in various electronic devices.

- There is a shortage of skilled labor, particularly in developing markets, which makes it difficult for companies to scale their operations and meet the growing demand for electronic products.

- Training and retaining talent is a key challenge in driving innovation and maintaining product quality.

Sustainability Concerns

- The increasing demand for eco-friendly products puts pressure on manufacturers of electronics adhesives to develop sustainable alternatives.

- Many conventional adhesives contain harmful chemicals that can have a negative impact on the environment during the production, use, or disposal stages.

- Developing adhesives that meet sustainability criteria while still performing effectively in electronic applications is a significant challenge.

Market Fragmentation

- The electronics adhesives market is fragmented, with numerous players offering a variety of solutions across different industries.

- The lack of standardization in terms of product offerings, technologies, and applications makes it difficult for businesses to differentiate themselves in the market.

- This fragmentation also leads to challenges in establishing strong market positioning and customer loyalty.

High Research and Development Costs

- The demand for high-performance adhesives tailored to specific applications, such as 5G, electric vehicles, and wearable electronics, requires substantial R&D investment.

- Developing new formulations that meet performance requirements and regulatory standards is a costly and time-consuming process.

- Smaller companies with limited budgets may find it challenging to invest in R&D and compete with established players in the market.

Longer Time-to-Market

- The process of developing and testing new electronics adhesives for various applications is often lengthy.

- Extensive testing for performance, environmental impact, and safety standards can result in longer time-to-market, delaying the introduction of new products.

- This extended development timeline can hinder companies from capitalizing on emerging market trends and consumer demands.

Customer Resistance to Change

- Many electronics manufacturers are used to working with traditional adhesive solutions, and there may be resistance to adopting newer, more innovative adhesives.

- Customers may be hesitant to switch to unfamiliar products, even if they offer superior performance, due to concerns over reliability, cost, or compatibility with existing systems.

- Overcoming this resistance requires educating customers on the benefits of new adhesives and demonstrating their advantages through trials and case studies.