Magnetic Separator Market Projected to Reach USD 1,192.25 Million by 2030

Rising Industrialization and Recycling Activities Propel Market Growth

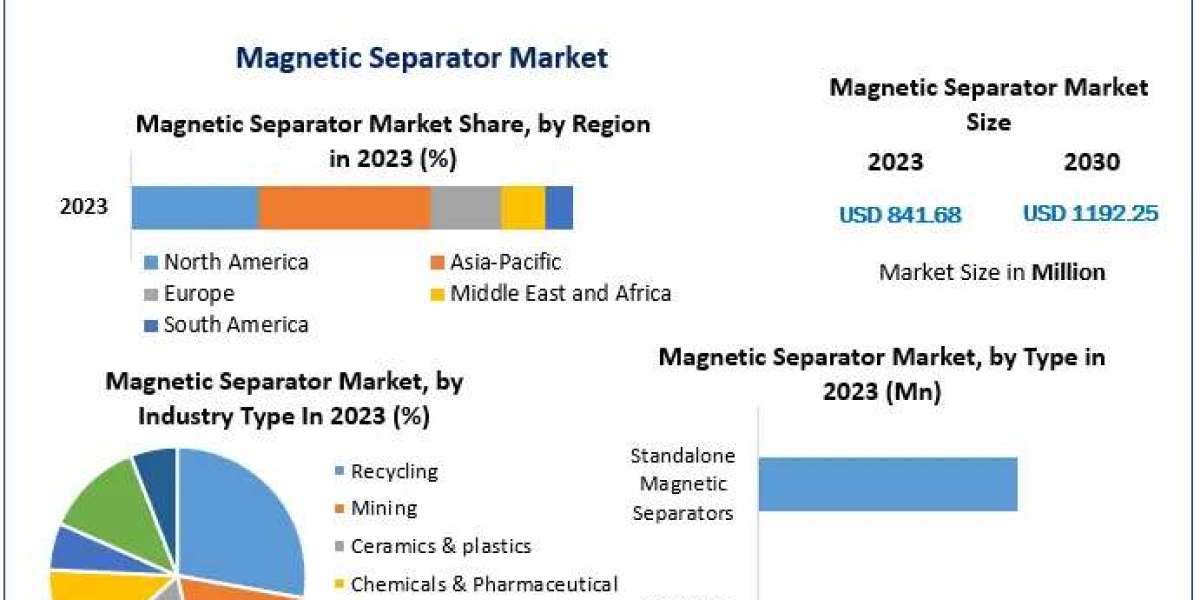

The global Magnetic Separator Market Statistics is experiencing significant expansion, with its valuation standing at USD 841.68 million in 2023 and projected to reach USD 1,192.25 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.1% during the forecast period. This growth is driven by increased industrial activities, particularly in mining and recycling sectors, and a heightened focus on environmental sustainability.

Market Definition and Overview

Magnetic separators are devices that utilize magnetic fields to separate magnetic materials from non-magnetic ones. This technique is essential in various industries for removing ferrous contaminants from products, ensuring product purity, and protecting processing equipment. Applications range from mining, where magnetic separators extract valuable minerals, to recycling, where they aid in sorting ferrous metals from waste streams.

To delve deeper into this research, please follow this link: https://www.maximizemarketresearch.com/request-sample/116659/

Market Growth Drivers and Opportunities

Several factors contribute to the robust growth of the magnetic separator market:

Industrial Expansion: The surge in industrial activities, especially in emerging economies, has led to increased demand for efficient separation technologies. In the mining industry, magnetic separators are crucial for the extraction and processing of minerals, enhancing product quality and operational efficiency.

Recycling Initiatives: Growing environmental concerns and stringent regulations have amplified recycling efforts globally. Magnetic separators play a pivotal role in recycling processes by efficiently separating ferrous metals from non-metallic materials, thereby facilitating material recovery and reducing landfill waste.

Technological Advancements: Innovations in magnetic separation technology, such as the development of high-gradient magnetic separators and automated systems, have improved separation efficiency and broadened application areas. These advancements offer opportunities for market expansion into new sectors and applications.

Food and Beverage Industry Compliance: The food and beverage sector's stringent quality standards necessitate the removal of metal contaminants to ensure consumer safety. Magnetic separators are employed to detect and eliminate ferrous particles during food processing, thereby complying with safety regulations and maintaining product integrity.

Segmentation Analysis

The magnetic separator market is segmented based on type, magnet type, cleaning type, and application.

By Type:

Equipment: This segment includes various magnetic separation devices such as overband magnets, magnetic pulleys, and eddy current separators. These are widely used in industries like mining and recycling to remove ferrous contaminants from bulk materials.

Standalone Magnetic Separators: These are individual units designed for specific applications, often used in smaller-scale operations or specialized processes where integration into existing systems is not feasible.

By Magnet Type:

Permanent Magnets: Utilizing materials like ferrite or rare-earth elements, permanent magnets provide a constant magnetic field without the need for external power. They are favored for their durability and low maintenance requirements.

Electromagnets: Powered by electricity, electromagnets offer adjustable magnetic strength, making them suitable for applications requiring variable separation intensity. They are commonly used in heavy industrial applications where high magnetic force is necessary.

By Cleaning Type:

Manual Cleaning: Involves periodic manual removal of accumulated ferrous materials from the separator. This method is cost-effective but may require process interruptions for cleaning.

Automatic Cleaning: Features self-cleaning mechanisms that continuously remove ferrous contaminants without manual intervention, ensuring uninterrupted operation and higher efficiency.

By Application:

Mining: Magnetic separators are extensively used in mining operations to extract valuable ferrous minerals and remove impurities from ores, enhancing the quality of the final product.

Recycling: In recycling facilities, magnetic separators aid in sorting ferrous metals from non-metallic materials, facilitating efficient recycling processes and material recovery.

Ceramics: Employed to remove iron contaminants from ceramic materials, ensuring the purity and quality of ceramic products.

Paper and Plastics: In the paper industry, magnetic separators remove ferrous contaminants from pulp, while in plastics processing, they ensure the purity of plastic products by eliminating metal particles.

Intrigued to explore the contents? Secure your hands-on sample copy of the report: https://www.maximizemarketresearch.com/request-sample/116659/

Country-Level Analysis

United States: The U.S. magnetic separator market is driven by advancements in recycling technologies and stringent environmental regulations promoting waste management and material recovery. The country's well-established mining industry also contributes to the demand for efficient separation solutions.

Germany: As a leader in industrial manufacturing and environmental initiatives, Germany exhibits substantial growth in the magnetic separator market. The nation's strong emphasis on recycling and sustainable practices, coupled with its advanced automotive and machinery sectors, fuels the demand for magnetic separation technologies.

Competitive Landscape

The magnetic separator market is characterized by the presence of key players focusing on innovation, strategic partnerships, and expanding their product portfolios. Notable companies in the market include:

Eriez Manufacturing Co.: A global leader in separation technologies, Eriez offers a comprehensive range of magnetic separators catering to various industries, emphasizing innovation and quality.

Metso Corporation: Specializing in mining and aggregates, Metso provides advanced magnetic separation solutions designed to enhance operational efficiency and product quality.

Bunting Magnetics Co.: Known for its diverse product offerings, Bunting Magnetics delivers customized magnetic separation equipment tailored to specific industry needs.

STEINERT GmbH: With a focus on resource recovery and recycling, STEINERT develops high-performance magnetic separators that contribute to efficient material sorting and waste reduction.

Conclusion

The global magnetic separator market is poised for substantial growth, driven by increased industrialization, environmental sustainability efforts, and technological advancements. As industries continue to prioritize efficiency and compliance with environmental regulations, the demand for effective magnetic separation solutions is expected to rise, offering significant opportunities for market participants.

Want a comprehensive market analysis? Check out the summary of the research report: https://www.maximizemarketresearch.com/market-report/global-magnetic-separator-market/116659/

Discover What's Trending:

Cotton Spinning Machine Market https://www.maximizemarketresearch.com/market-report/cotton-spinning-machine-market/74538/

Online Food Delivery Market https://www.maximizemarketresearch.com/market-report/global-online-food-delivery-market/88636/

3rd Floor, Navale IT park Phase 2,

Pune Banglore Highway, Narhe

Pune, Maharashtra 411041, India.

+91 9607365656

[email protected]