This kind of incapacity might be probably the most very important obstacle to of us finishing up widespread, on a regular basis actions resembling private hygiene, work, and hobbies. When an individual additionally has low cost of or lack of lower limb perform, the bodily and psychologic lack of management is profound, and the disabled individual turns into relying on others in just about every respect. Rehabilitation robotics tries to alleviate this case by utilizing manipulators to revive manipulative perform and clever wheelchairs to supply mobility. The industrial robots organizations for which our present enchancment is supposed share the widespread attribute of requiring a system that facilitates the programming of enterprise robots. This demand arises from the reality that the robotic have to be prepared to hold out a given job with a small number of repetitions.

This spurred further analysis and technical enchancment and objects comparable to the event of the microprocessor helped to create cost-effective administration methods which have been nonetheless highly effective. They appear like a human arm, which is why they’re additionally known as robotic arm or manipulator arm. Their articulations with numerous ranges of freedom allow the articulated arms a in depth vary of actions. Ultimately, builders have been able to create further complicated motions, placed on exterior sensors, and add further purposes resembling welding, grinding, deburring, and assembly. Since then, industrial robots have been capable of reduce prices, enhance productiveness, enhance prime quality, and help takeover dangerous or harmful duties. Considerably improved robotic system performances and an elevated ease of use open up new automation options, a lot of that are exterior the “basic” purposes of enterprise industrial robots.

Some robotic producers moreover level out alignment singularities, the place axes 1 and 6 flip into coincident. When the robotic passes near a shoulder singularity, joint 1 spins very fast. Variety of axes – two axes are required to succeed in any stage in a plane; three axes are required to succeed in any stage in home.

Within the 12 months 2020, an estimated 1.64 million industrial robots have been in operation worldwide in keeping with Worldwide Federation of Robotics . ROS-Industrial is an open-source mission that extends the superior capabilities of ROS software program program to industrial related {hardware} and features. The kind of movement is dictated by the affiliation of joints and linkages. Taking that digital babysitter, as an illustration, a “good AI babysitter” may pretty put a baby in a discipline or cage to maintain it from harming itself or the setting. Youngsters and adults, sadly, sometimes needs to be taught from so much, rather more disastrous errors. Nevertheless, AI observers ought to all the time take note of the normal hierarchy of knowledge, which progresses from raw data to information to information, after which data.

With out sensors and different newest developments, none of this may be potential. AI will reshape the capabilities of robotic expertise, nevertheless that is nonetheless a minimal of a decade sooner or later. Within the meantime, AI may assist companies take a inhabitants of robots that do the similar job and supply all the information to a centralized location, which in return can be utilized to make that full community of robots smarter and further atmosphere pleasant. With anyplace from two to 10 joints, articulated robots are associated to the underside with a twisting joint. Resembling a human arm, they’re typically utilized in packaging, portray, metal casting and completely different industrial functions. Sensors and imaginative and prescient strategies allow robots to reply their exterior setting in real-time, growing the vary of duties the robotic can carry out – much like choosing and inserting unsorted parts – and growing robotic mobility.

UR+ Ecosystem UR+ provides entry to peripherals and utility kits designed to your success. The TI-RSLK MAX comes with 20 studying modules overlaying core to supplemental topics with lecture movies, lab demonstrations, quizzes and classroom actions. The curriculum is concentrated to indicate embedded methods and features and could also be expanded and utilized in numerous engineering programs at any diploma alongside a university pupil’s finding out journey. Our robotic specialists clear, examine, and restore your robots to revive them to like-new scenario and prolong use. This was adopted by the tentacle arm, designed by Marvin Minsky in 1968. Robots routinely assemble merchandise, eliminating tedious and tiresome duties.

We’ll be joyful to answer any questions you would have, merely click on under to get began. How good, linked robots are remodeling manufacturing © IFRFor extra data, please focus on with the IFR Info Paper on How Linked Robots are Reworking Manufacturing. Please assist enhance this part by including citations to reliable sources. To be succesful of transfer and orient the effector organ in all instructions, such a robotic wants 6 axes .

The conduct of such strategies is intrinsically dominated by bodily legal guidelines, resembling Newton’s legal guidelines. Creating an engineering system requires not solely info of the bodily legal guidelines, however as well as the talents to use such information in developing a system. In frequent, intelligence refers once more to the flexibility to construct up such information and experience, and to use them , with the intention to obtain sure targets. Industrial robots have been improved remarkably and utilized to numerous duties comparable to dealing with, painting, welding, sealing and so forth. Devoted robots designed to fulfill the exact wants of each enterprise from cleanrooms to harsh environments.

An Industrial Robotic is printed by ISO 8373 as an mechanically managed, reprogrammable, multipurpose manipulator, programmable in three or extra axes. Profit from a fast ROI as a consequence of low-cost elements from foremost producers. Common Robots might keep monitor of my identify and enterprise contact info to e-mail me thrilling updates in manufacturing facility automation which is perhaps associated to me. As robots have gotten further important in factories, it is essential that they become further clever, autonomous, safer and environment friendly. All of that’s enabled with applied sciences comparable to actual motor administration, superior sensing applied sciences and processing on the edge, all with sturdy real-time communication.

They will additionally automate capabilities involved inside the transferring of parts from one piece of apparatus to a different. Direct labor costs are lowered and much of the tedious and unsafe actions historically carried out by human labor are eradicated. OSARO declares a refined technique and suite of merchandise that provides full, devoted, and built-in options packages for e-commerce, cosmetics and grocery success. KUKA releases model 4.0 of the KUKA.sim digital robotic simulation software program. The launch consists of superior programming options together with new safety simulation capabilities.

Lastly, robots don’t require the similar home as people, which means producers can greater make the most of their floor home to suit further stock or manufacturing strains. For instance, broad aisleways initially meant for human navigation could also be condensed to allow for the minimal required clearance for a robotic to navigate. Industrial robots can full routine duties at a continuing prime quality and velocity, which could permit extra predictable and elevated manufacturing output and ensures merchandise are always crafted with the identical specs. Industrial robots’ functionality to finish routine duties moreover permits workers to be assigned to work in roles that are every further complicated and fulfilling, as properly as much less hazardous. They’re composed of a sequence of joints and linkages that go from the underside to the robotic system.

Utilizing clever vitality administration methods they supply most effectivity for the least attainable vitality. Simple to Restore Our exacting necessities and 100% high quality make sure that our industrial robots common as so much as 3850 hours earlier than we advise finishing up preventive upkeep. Collaborative and standard industrial robots © IFR Worldwide Federation of Robotics For further data, please consult with the IFR Positioning Paper on Demystifying Collaborative Robots and case analysis. The train pendant or PC is often disconnected after programming and the robotic then runs on this system that has been put in in its controller. Nevertheless a pc is often used to ‘supervise’ the robotic and any peripherals, or to supply further storage for entry to quite a few superior paths and routines.

The Stanford Arm was one of many first electronically powered, computer-controlled arms. By 1974, it reached a level of sophistication the place it could assemble a Mannequin T water pump. Constructing dexterity into robots provides a producing alternative that’s in any other case very troublesome to automate. An instance of that is the manufacturing of orthopedic implants, much like knee and hip joints. Buffing and sharpening a hip joint by hand can usually take minutes whereas a robotic can carry out the identical perform in just some minutes. Industrial robots have revolutionized the industrial office all through industries since their introduction to the manufacturing panorama.

The primary worthwhile story of a enterprise rising a particular robotic based totally on their desires was created in 1967. This firm developed a robotic to finish a twig painting utility and finally turned ABB. This is only one instance of when large companies began to develop their very personal industrial robots. Others in addition to, machine operators sometimes use person interface devices, generally touchscreen fashions, which function the operator administration panel. The operator can swap from program to program, make changes inside a program and moreover function numerous peripheral items that might be built-in all through the same robotic system. With their good design, extreme effectivity and dexterity, Stäubli’s 6 axis robots are perfect for many industries and functions.

As a prohibit, the system ought to have the flexibleness to carry out a given job solely as shortly as after which it must be programmed as soon as extra to hold out a particular one. The CL data generated by the CAD/CAM system have info of factors alongside the curved flooring and their regular vectors. This system permits us to generate the desired trajectory with out educating and to reinforce the effectivity of profiling administration. Nevertheless, it have to be thought of how the sprucing robotic could also be utilized to such an object as is manufactured with out CAD/CAM system. The primary prototype, Unimate, was produced in 1961 and put in in GM’s manufacturing unit for die casting dealing with and spot welding.

Elevated use of robots may also be enabling companies in excessive worth worldwide areas to ‘re-shore’ or convey again to their home base elements of the provision chain that they’ve beforehand outsourced to sources of cheaper labor. The reason why corporations take into consideration investing in a robotic system differ broadly. China is the most important industrial robotic market, with 154,032 fashions provided in 2018. China had an important operational inventory of business robots, with 649,447 on the top of 2018. America industrial robot-makers shipped 35,880 robotic to factories within the US in 2018 and this was 7% higher than in 2017. A second kind of singularity in wrist-partitioned vertically articulated six-axis robots happens when the wrist heart lies on a cylinder that’s centered about axis 1 and with radius equal to the hole between axes 1 and 4.

In addition to, this technique isn’t environment friendly for a cell base with a manipulator. If low energy actuators are adopted inside the cell base, it does not switch properly. Configure your robolink® articulated arm robotic primarily based in your requirements and simulate movement sequences. UR Academy Get started and advance your automation journey with award-winning robotics teaching and free e-learning. Service360 Maximize uptime to your cobot with a tailored service program.

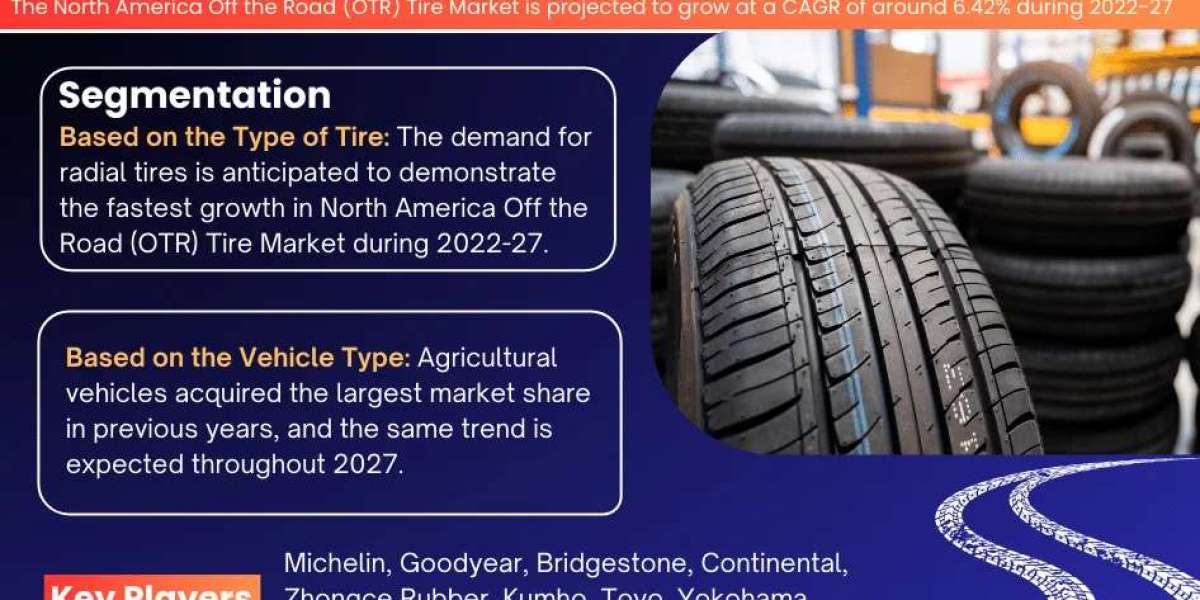

It’s projected to be worth greater than $66 billion by 2027, exhibiting a CAGR of 15.1% through the forecast interval. RoboTire is automating shopper tire altering by utilizing industrial robotic arms to complete a tire change in as little as quarter-hour. You’ll on a regular basis discover the very best one, irrespective of how difficult the making use of. With higher than 250 software program program features for enhanced intelligence, movement, security and productiveness and a broad number of FANUC high quality equipment, we have an answer for almost every conceivable software program. FANUC’s FIELD system Zero Down Time software program is designed to eliminate down time and enhance whole robotic efficiency. Whereas FANUC robots are extremely reliable, producers nonetheless want a solution to maximise uptime.

A robotic and a group of machines or peripherals is named a workcell, or cell. A typical cell might comprise a elements feeder, a molding machine and a robotic. The assorted machines are ‘built-in’ and managed by a single pc or PLC. How the robotic interacts with completely different machines within the cell must be programmed, every with regard to their positions inside the cell and synchronizing with them. All-in-one software program program comprises a simulation carry out, providing an environment friendly strategy to deploy features.

Injection molds, dies, or electrical discharge machining electrodes might be fabricated simply on this technique. As well as, novel constructions or assemblies that are deemed infeasible with commonplace manufacturing processes might be made. For example, composites and laminates of metals, plastics, and ceramics might be shaped. Assemblies that are of extreme packing density, composed of selective supplies deposition inside each layer, or made up of parts usual and embedded in a single construction could also be put collectively. Industrial functions of robots are certain to develop in different non-traditional areas.